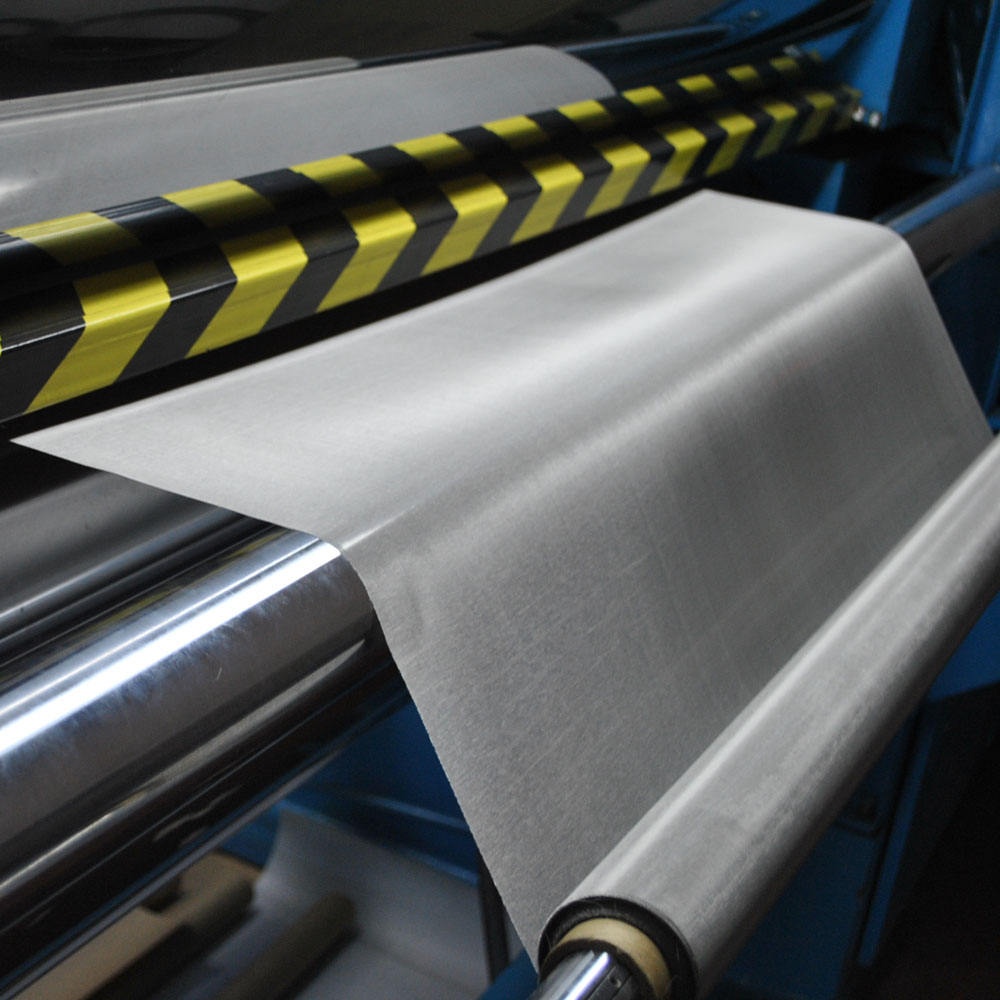

Stainless steel woven wire mesh is a type of wire mesh made from high-quality stainless steel wires. It is widely used in various industrial applications, such as filtration, separation, and protection.

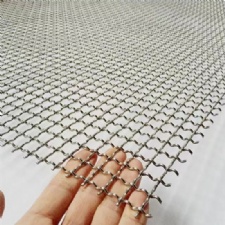

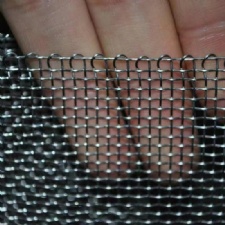

Stainless steel woven wire mesh is available in two basic types of weaves: plain weave and Dutch weave. In plain weave, the wires are woven together in a simple criss-cross pattern, while in Dutch weave, the wires are woven in a tighter pattern with larger diameter warp wires and smaller diameter weft wires. This creates a mesh with a larger open area and greater strength.

Stainless steel woven wire mesh is available in a wide range of mesh sizes, from 2-micron aperture to 40mm aperture. The mesh size is determined by the number of wires per inch or the distance between two adjacent wires.

The table provided in the previous answer lists the specifications of stainless steel woven wire mesh available in plain and twilled weave. It includes the mesh size, wire diameter, opening width, and opening area percentage for each size of wire mesh. These specifications can help users choose the right type of wire mesh for their specific application.

Specifications of Stainless steel woven wire mesh

Plain weave is a simple and common type of weave that involves weaving the wires together in an over-and-under pattern, with each wire passing over one and under the next adjacent wire. The result is a grid-like pattern with evenly spaced wires running perpendicular to each other. This creates a strong and durable mesh with a uniform appearance.

Twilled weave, on the other hand, is a more complex weave pattern that involves each wire passing over and under two adjacent wires in a staggered pattern. This creates a diagonal pattern in the mesh, which can provide greater strength and durability compared to plain weave. Twilled weave also allows for greater variation in wire diameter and mesh count, making it a versatile option for a range of applications.

Both plain weave and twilled weave stainless steel woven wire mesh have their advantages and disadvantages, and the choice of weave will depend on the specific requirements of the application. For example, plain weave is generally better for applications that require a fine mesh and high levels of filtration, while twilled weave is better for applications that require higher strength and durability.

Specifications

|

PLAIN AND TWILLED WEAVE |

|||||

|

Mesh |

Wire Diameter |

Opening Width |

Opening Area% |

||

|

inches |

mm |

inches |

mm |

||

|

1mesh |

0.135 |

3.5 |

0.865 |

21.97 |

74.8 |

|

1mesh |

0.12 |

3 |

0.88 |

22.35 |

77.4 |

|

1mesh |

0.105 |

2.5 |

0.895 |

22.73 |

80.1 |

|

1mesh |

0.08 |

2 |

0.92 |

23.36 |

84.6 |

|

1mesh |

0.063 |

1.6 |

0.937 |

23.8 |

87.70% |

|

2mesh |

0.12 |

3 |

0.38 |

9.65 |

57.8 |

|

2mesh |

0.105 |

2.5 |

0.395 |

10.03 |

62.4 |

|

2mesh |

0.08 |

2 |

0.42 |

10.66 |

70.6 |

|

2mesh |

0.063 |

1.6 |

0.437 |

11.1 |

76.4 |

|

2 mesh |

0.047 |

1.2 |

0.453 |

11.5 |

82.1 |

|

2mesh |

0.41 |

10.4 |

0.459 |

11.65 |

84.3 |

|

3mesh |

0.08 |

2 |

0.253 |

6.42 |

57.6 |

|

3mesh |

0.063 |

1.6 |

0.27 |

6.85 |

65.6 |

|

3 mesh |

0.047 |

1.2 |

0.286 |

7.26 |

73.6 |

|

3mesh |

0.032 |

0.81 |

0.3 |

7.62 |

81.5 |

|

4mesh |

0.12 |

3 |

0.13 |

3.3 |

27 |

|

4 mesh |

0.08 |

2 |

0.17 |

4.31 |

46.2 |

|

4 mesh |

0.063 |

1.6 |

0.187 |

4.75 |

56 |

|

4 mesh |

0.047 |

1.2 |

0.203 |

5.15 |

65.9 |

|

4mesh |

0.035 |

0.89 |

0.218 |

5.53 |

76 |

|

4mesh |

0.028 |

0.71 |

0.222 |

5.62 |

78.9 |

|

4mesh |

0.025 |

0.63 |

0.225 |

5.71 |

81 |

|

5mesh |

0.08 |

2 |

0.12 |

3.04 |

36 |

|

5mesh |

0.047 |

1.2 |

0.153 |

3.88 |

58.5 |

|

5mesh |

0.041 |

1 |

0.159 |

4.01 |

63.2 |

5mesh-Stainless Steel Woven Wire Mesh |

0.023 |

0.58 |

0.177 |

4.49 |

78.3 |

|

6mesh |

0.063 |

1.6 |

0.104 |

2.64 |

38.9 |

|

6mesh |

0.047 |

1.2 |

0.12 |

3.04 |

51.8 |

|

6mesh |

0.035 |

0.9 |

0.132 |

3.35 |

62.7 |

|

8mesh |

0.063 |

1.6 |

0.062 |

1.57 |

24.6 |

|

8mesh |

0.047 |

1.2 |

0.078 |

1.98 |

38.9 |

|

8mesh |

0.035 |

0.9 |

0.09 |

2.28 |

51.8 |

|

8mesh |

0.032 |

0.8 |

0.093 |

2.36 |

55.4 |

|

8mesh |

0.028 |

0.7 |

0.097 |

2.46 |

60.2 |

|

8mesh |

0.023 |

0.58 |

0.102 |

2.59 |

66.6 |

|

8mesh |

0.017 |

0.43 |

0.108 |

2.74 |

74.6 |

|

10mesh |

0.047 |

1.2 |

0.053 |

1.34 |

28.1 |

|

10mesh |

0.035 |

0.9 |

0.065 |

1.65 |

42.3 |

|

10mesh |

0.032 |

0.8 |

0.068 |

1.27 |

46.2 |

|

10mesh |

0.025 |

0.63 |

0.075 |

1.9 |

56.3 |

10mesh-Stainless Steel Woven Wire Mesh |

0.02 |

0.5 |

0.08 |

2.03 |

64 |

|

12mesh |

0.041 |

1 |

0.042 |

1.06 |

25.4 |

|

12mesh |

0.035 |

0.9 |

0.048 |

1.22 |

33.2 |

|

12mesh |

0.032 |

0.8 |

0.051 |

1.29 |

37.5 |

|

12mesh |

0.028 |

0.7 |

0.055 |

1.39 |

43.6 |

|

12mesh |

0.023 |

0.58 |

0.06 |

1.52 |

51.8 |

|

12mesh |

0.018 |

0.45 |

0.065 |

1.65 |

60.8 |

|

12mesh |

0.013 |

0.33 |

0.07 |

1.77 |

70.6 |

|

14mesh |

0.032 |

0.8 |

0.039 |

1.52 |

29.8 |

|

14mesh |

0.025 |

0.63 |

0.046 |

0.99 |

41.5 |

|

14mesh |

0.023 |

0.58 |

0.048 |

1.22 |

45.2 |

|

14mesh |

0.02 |

0.5 |

0.051 |

1.3 |

51 |

|

16mesh |

0.032 |

0.8 |

0.031 |

0.78 |

23.8 |

|

16mesh |

0.028 |

0.7 |

0.035 |

0.89 |

30.5 |

|

16mesh |

0.023 |

0.58 |

0.04 |

1.01 |

39.9 |

|

16mesh |

0.018 |

0.45 |

0.045 |

1.14 |

50.7 |

|

16mesh |

0.009 |

0.23 |

0.054 |

1.37 |

73.3 |

|

18mesh |

0.02 |

0.5 |

0.036 |

0.91 |

41.1 |

|

18mesh |

0.018 |

0.45 |

0.038 |

0.96 |

48.3 |

|

18mesh |

0.009 |

0.23 |

0.047 |

1.19 |

70.4 |

|

20mesh |

0.023 |

0.58 |

0.027 |

0.68 |

29.2 |

|

20mesh |

0.02 |

0.5 |

0.03 |

0.76 |

36 |

|

20mesh |

0.018 |

0.45 |

0.032 |

0.81 |

41 |

|

20mesh |

0.016 |

0.4 |

0.034 |

0.86 |

46.2 |

|

20mesh |

0.014 |

0.35 |

0.036 |

0.91 |

51.8 |

|

20mesh |

0.009 |

0.23 |

0.041 |

1.04 |

67.2 |

|

24mesh |

0.014 |

0.35 |

0.028 |

0.71 |

44.2 |

|

28mesh |

0.01 |

0.25 |

0.026 |

0.66 |

51.8 |

|

30mesh |

0.013 |

0.33 |

0.02 |

0.5 |

37.1 |

|

30mesh |

0.012 |

0.3 |

0.021 |

0.53 |

40.8 |

|

30mesh |

0.011 |

0.28 |

0.022 |

0.55 |

44.8 |

|

30mesh |

0.0065 |

0.16 |

0.027 |

0.68 |

64.8 |

|

35mesh |

0.012 |

0.3 |

0.017' |

0.43 |

33.8 |

|

35mesh |

0.01 |

0.25 |

0.019 |

0.48 |

42.4 |

40mesh |

0.014 |

0.35 |

0.011 |

0.28 |

19.3 |

|

40mesh |

0.012 |

0.3 |

0.013 |

0.33 |

27.4 |

|

40mesh |

0.01 |

0.25 |

0.015 |

0.38 |

36 |

|

40mesh |

0.0095 |

0.24 |

0.016 |

0.4 |

38.4 |

|

50mesh |

0.009 |

0.23 |

0.011 |

0.28 |

30.3 |

|

50mesh |

0.008 |

0.20` |

0.012 |

0.3 |

36 |

|

60mesh |

0.0075 |

0.19 |

0.009 |

0.22 |

30.5 |

|

60mesh |

0.0059 |

0.15 |

0.011 |

0.28 |

40.2 |

|

70mesh |

0.0065 |

0.17 |

0.008 |

0.2 |

29.8 |

|

80mesh |

0.007 |

0.18 |

0.006 |

0.15 |

19.4 |

|

80mesh |

0.0055 |

0.14 |

0.007 |

0.17 |

31.4 |

|

80mesh |

0.0047 |

0.12 |

0.0088 |

0.22 |

49.6 |

|

90mesh |

0.0055 |

0.14 |

0.006 |

0.15 |

25.4 |

100mesh-Stainless Steel Woven Wire Mesh |

0.0045 |

0.11 |

0.006 |

0.15 |

30.3 |

|

120mesh |

0.004 |

0.1 |

0.0043 |

0.11 |

26.6 |

|

120mesh |

0.0037 |

0.09 |

0.005 |

0.12 |

30.7 |

|

130mesh |

0.0034 |

0.0086 |

0.0043 |

0.11 |

31.2 |

|

150mesh |

0.0026 |

0.066 |

0.0041 |

0.1 |

37.4 |

|

165mesh |

0.0019 |

0.048 |

0.0041 |

0.1 |

44 |

|

180mesh |

0.0023 |

0.058 |

0.0032 |

0.08 |

33.5 |

|

180mesh |

0.002 |

0.05 |

0.0035 |

0.09 |

41.1 |

200mesh |

0.002 |

0.05 |

0.003 |

0.076 |

36 |

|

200mesh |

0.0016 |

0.04 |

0.0035 |

0.089 |

46 |

|

220mesh |

0.0019 |

0.048 |

0.0026 |

0.066 |

33 |

|

230mesh |

0.0014 |

0.035 |

0.0028 |

0.071 |

46 |

|

250mesh |

0.0016 |

0.04 |

0.0024 |

0.061 |

36 |

|

270mesh |

0.0014 |

0.04 |

0.0022 |

0.055 |

38 |

|

300mesh |

0.0012 |

0.03 |

0.0021 |

0.053 |

40.1 |

|

325mesh |

0.0014 |

0.04 |

0.0017 |

0.043 |

30 |

|

325mesh |

0.0011 |

0.028 |

0.002 |

0.05 |

42 |

|

400mesh |

0.001 |

0.025 |

0.0015 |

0.038 |

36 |

|

500mesh |

0.001 |

0.025 |

0.0011 |

0.028 |

25 |

|

635mesh |

0.0009 |

0.022 |

0.0006 |

0.015 |

14.5 |

Specification Reference of Stainless Steel Fine Wire Cloth Dutch Woven |

||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||

Here are some common applications of stainless steel woven wire mesh:

-

Filtration: Stainless steel woven wire mesh is commonly used in filtration applications due to its high strength and corrosion resistance. It can be used to filter solids, liquids, and gases in a variety of applications such as water treatment, chemical processing, and food and beverage production.

-

Sieving and sorting: Stainless steel woven wire mesh is often used to sort and separate materials of different sizes. It is commonly used in mining, quarrying, and construction industries to sieve rocks and soil, as well as in the agricultural industry to separate grains and seeds.

-

Security and protection: Stainless steel woven wire mesh can be used as a protective barrier in various applications such as window screens, fencing, and enclosures. It can also be used to reinforce walls and ceilings to prevent break-ins and protect against impact.

-

Decorative purposes: Stainless steel woven wire mesh can be used for aesthetic purposes such as decorative screens, wall cladding, and architectural elements in buildings and outdoor spaces.

-

Industrial applications: Stainless steel woven wire mesh is used in various industrial applications such as conveyor belts, industrial sieves, and machine guards due to its high strength, durability, and resistance to corrosion and heat.

Overall, stainless steel woven wire mesh is a versatile material that can be used in a wide range of applications across various industries due to its strength, durability, and corrosion resistance.

High quality wire,High Tension Low Elongation,Super Preciision etc

Calendering making screen thinner and obtaning flat

Stainless steel woven wire mesh can be produced in different weave types to meet different application requirements. Here is a brief description of each weave type:

-

Plain Weave: This is the most common and simplest weave type, where each wire is woven alternately over and under the adjacent wires in both directions, forming a square opening.

-

Twill Weave: In this weave type, each wire passes alternately over and under two wires, creating a diagonal pattern. This weave is stronger than the plain weave and can handle higher tensile loads.

-

Plain Dutch Weave: This weave type is similar to the plain weave but with thicker warp wires and thinner weft wires. The openings are smaller and more rectangular, making it suitable for filtration applications.

-

Twill Dutch Weave: This weave type combines the twill weave and the plain Dutch weave, creating a diagonal pattern with rectangular openings. It is commonly used for high-pressure filtration.

-

Reverse Dutch Weave: In this weave type, the warp wires are thicker and have a larger diameter than the weft wires, creating a tight mesh with smaller openings. It is ideal for fine filtration applications.

-

Rectangular Weave: This weave type has rectangular openings and is commonly used for architectural and decorative purposes.

-

Five Heddle Weave: This weave type uses five warp wires and one weft wire to create a square opening. It has a smooth surface and is commonly used for fine filtration.

-

Multiplex Weave: This weave type uses multiple layers of wires in both directions to create a thick and strong mesh. It is commonly used for heavy-duty filtration and industrial applications.

Each weave type has its own unique properties and advantages, and choosing the right weave type depends on the specific application requirements.

packing it is important to take several factors into consideration to ensure that the mesh arrives at its destination in good condition.

-

Protection: The mesh should be protected from scratches and other types of damage during transportation. Wrapping it in a layer of bubble wrap or foam can help prevent any surface damage.

-

Stacking: When packing multiple sheets of mesh, they should be stacked flat and not on their edges. This will help prevent any warping or bending of the mesh.

-

Labeling: Each package should be clearly labeled with the size and type of mesh contained inside. This will help ensure that the mesh is easily identifiable upon arrival.

-

Moisture: Stainless steel mesh is susceptible to corrosion from moisture, so it is important to pack it in a dry environment. A desiccant pack can be included in the package to help absorb any excess moisture.

-

Packaging material: The packaging material used should be strong and durable enough to withstand the rigors of transportation. A sturdy cardboard box or crate is recommended for shipping the mesh.

Overall, taking these precautions when packing stainless steel woven wire mesh will help ensure that it arrives at its destination in good condition, ready for use.

Boss Metal And Plastic Co Limited

Boss Metal And Plastic Co Limited