316 stainless steel perforated sheet is a versatile metal mesh product used in a variety of applications, including architectural, industrial, and decorative. Perforated metal sheets are created by uniformly punching holes in sheets or coils of metal, resulting in various hole sizes, shapes, and configurations. The 316 stainless steel perforated sheet is popular because of its corrosion resistance and durability, making it an excellent choice for outdoor and indoor applications.

-

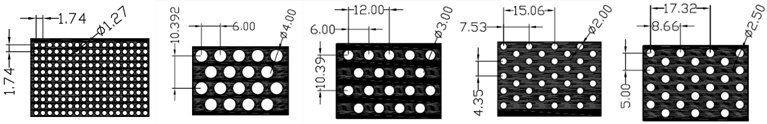

Round Hole 316 Stainless Steel Perforated Sheet Round hole perforated sheets are the most common type of perforated metal and offer a wide range of hole sizes, gauges, materials, and sheet sizes. These perforated sheets are widely used in applications such as cladding and ceiling panels, sunshades and sunscreens, filters, decorative banisters, and protective fences for overpasses and machines.

The 316 stainless steel round hole perforated sheet can provide privacy for building occupants without obstructing the view. Additionally, it features interior climate control to reduce the air conditioning load and save energy. Perforated fences and banisters enhance the safety of people and keep enclosed machines and other properties from damage.

Our company specializes in manufacturing round hole perforated sheets using high-quality materials, including mild or carbon steel, galvanized or PVC coated steel, stainless steel, aluminum, copper, and brass.

Specifications round hole

| Description | Hole Size (mm) | Pitch (mm) | Open Rate | Sheet Thickness |

|---|---|---|---|---|

| R0.8 T2 | 0.80 | 2.00 | 15% | * |

| R1 T2 | 1.00 | 2.00 | 23% | * |

| R1.2 T2.25 | 1.20 | 2.25 | 26% |

|

| R1.2 T2.5 | 1.20 | 2.50 | 21% |

|

| R1.5 T2.75 | 1.50 | 2.75 | 27% |

|

| R1.5 T3 | 1.50 | 3.00 | 23% |

|

| R1.8 T3.5 | 1.80 | 3.50 | 24% |

|

| R2 T3 | 2.00 | 3.00 | 40% |

|

| R2 T3.5 | 2.00 | 3.50 | 30% |

|

| R2 T4 | 2.00 | 4.00 | 23% |

|

| R2.5 T3.5 | 2.50 | 3.50 | 46% |

|

| R2.5 T4 | 2.50 | 4.00 | 35% |

|

| R2.5 T4.5 | 2.50 | 4.50 | 28% |

|

| R2.5 T5 | 2.50 | 5.00 | 23% |

|

| R3 T5 | 3.00 | 5.00 | 33% |

|

-

Square Hole 316 Stainless Steel Perforated Sheet Square hole perforated sheets are an alternative to traditional round hole perforated sheets, punched by a square die. These sheets have a high open area, making them ideal for use as grilles, especially speaker grilles that allow sound to pass through easily while protecting the speaker from vibration damage. They are also used for shopfitting displays, offering excellent visibility.

Specification Square Hole

|

material |

thickness (mm) |

Aperture (mm) |

hole spacing (mm) |

wide (m) |

length (m) |

punching rate (%) |

weight (kg/m2) |

|

Coil sheet |

0.2 |

6 |

2 |

1 |

20 |

44 |

0.88 |

|

0.35 |

5 |

4 |

1 |

20 |

24 |

2 |

|

|

0.45 |

6 |

3 |

1 |

20 |

35 |

2.5 |

|

|

0.8 |

3 |

3 |

1 |

20 |

19.6 |

3 |

|

|

Flat sheet |

0.5 |

1 |

1 |

1 |

2 |

19.6 |

3.14 |

|

0.8 |

1.5 |

1.5 |

1 |

2 |

19.6 |

5 |

|

|

1.5 |

2 |

2 |

1 |

2 |

19.6 |

9.4 |

|

|

3 |

5 |

16 |

1 |

2 |

19.6 |

18.8 |

|

|

stainless metal plate |

0.5 |

1 |

1 |

1 |

2 |

19.6 |

3.14 |

|

0.8 |

1.5 |

1.5 |

1 |

2 |

19.6 |

5 |

|

|

1 |

2 |

2 |

1 |

2 |

19.6 |

6.28 |

|

|

2 |

5 |

16 |

1 |

2 |

19.6 |

6.28 |

|

|

aluminum plate |

0.5 |

1 |

1 |

1 |

2 |

19.6 |

1.08 |

|

0.8 |

3 |

3 |

1 |

2 |

19.6 |

1.72 |

|

|

1.5 |

2 |

2 |

1 |

2 |

19.6 |

3.24 |

|

|

2 |

4 |

16 |

1 |

2 |

19.6 |

|

The square hole 316 stainless steel perforated sheets are multifunctional safety and ventilation sheets. They are ideal for applications such as machine guards, air condition guards, computer server chassis, balconies, and balustrades.

Our company offers square hole perforated sheets made from high-quality materials, including mild or carbon steel, galvanized or PVC coated steel, stainless steel, aluminum, copper, and brass. The hole patterns are supplied in straight, staggered, and diagonal arrangements, with customizable hole sizes ranging from 3/4" to 200".

-

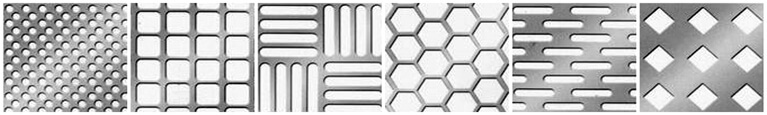

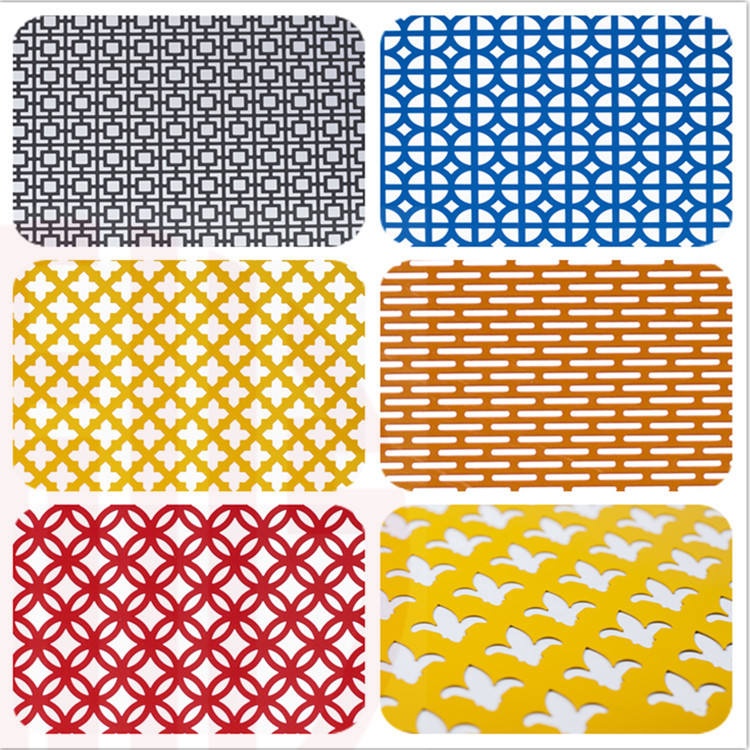

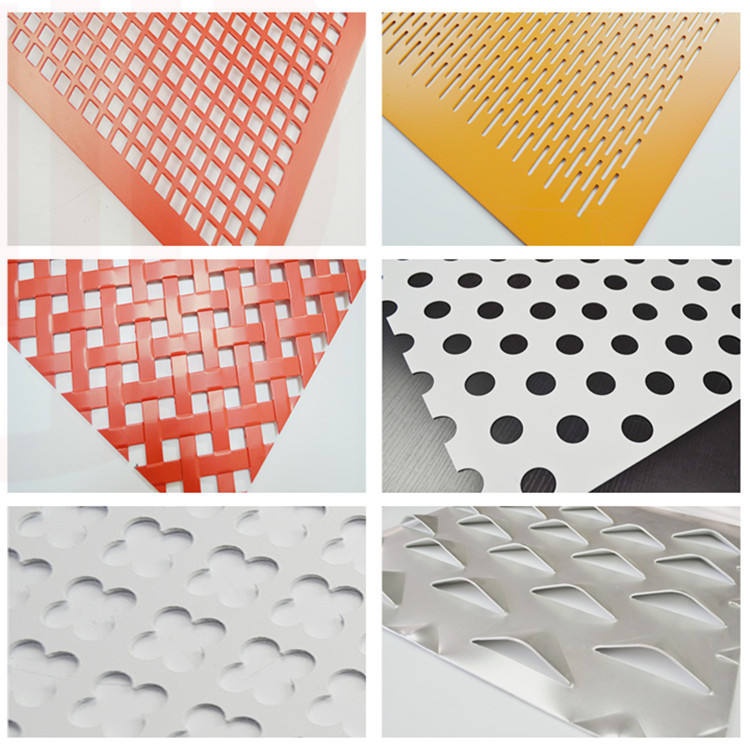

Hole Pattern of 316 Stainless Steel Perforated Sheet The 316 stainless steel perforated sheet is not limited to round and square perforated metal. We can shear or form the perforated sheets to any specification or desired shape, making them suitable for various applications, including industrial decoration, equipment guards, screens, ceilings, curtain walls, ventilation, and more.

Our company offers 316 stainless steel perforated sheets in various thicknesses and hole shapes according to the applications and project requirements. We keep more than 150 sets of molds to ensure they match clients' requirements, and we can also make design punch tooling suitable for architectural and decorative metal uses.

316 stainless steel perforated sheet has a wide range of applications due to its corrosion resistance, durability, and versatility. Some common applications include:

-

Architectural design: perforated sheet can be used for decorative elements in building facades, walls, ceilings, and partitions.

-

Filtration and separation: perforated sheet is often used for filters, strainers, screens, and separators in various industries such as oil and gas, water treatment, and food processing.

-

Acoustics: perforated sheet can be used in the construction of sound-absorbing panels and barriers to reduce noise levels in buildings, transportation vehicles, and industrial environments.

-

Furniture: perforated sheet can be used for design elements in furniture such as chairs, tables, and cabinets.

-

Automotive: perforated sheet is used for grilles, vents, and speaker covers in automobiles.

-

HVAC: perforated sheet is used for air diffusers, grilles, and screens in heating, ventilation, and air conditioning systems.

The production process of 316 stainless steel perforated sheet typically involves the following steps:

-

Material chooseion: The first step is to choose the appropriate grade of 316 stainless steel for the intended application. This may involve considering factors such as corrosion resistance, strength, and cost.

-

Perforation: The chooseed sheet is then perforated using a punching machine or laser cutter. The size, shape, and pattern of the holes can be customized based on the specific requirements of the application.

-

Cleaning and finishing: After perforation, the sheet is thoroughly cleaned to remove any debris or contaminants. It may then undergo additional finishing processes such as polishing or coating to enhance its appearance or performance.

-

Quality control: The finished product is inspected for quality and consistency to ensure that it meets the required specifications and standards.

In conclusion

the 316 stainless steel perforated sheet is a versatile metal mesh product that offers various hole sizes, shapes, and configurations, making it ideal for a wide range of applications. Our company specializes in manufacturing round and square hole perforated sheets using high-quality materials and customizable hole patterns and sizes to meet our clients' specific requirements.

Boss Metal And Plastic Co Limited

Boss Metal And Plastic Co Limited