Stainless steel wire cable mesh is a versatile and durable material that can be used in various applications where safety and protection are paramount. Some of the benefits of using stainless steel wire cable mesh include:

-

Instant safety solution: Stainless steel cable mesh is designed to provide instant protection against hazards such as rock collapse, roll-off, and blasting flying rocks.

-

Fast and easy installation: Stainless wire cable mesh can be installed quickly and easily, without the need for any special tools or equipment.

-

Customizable: Stainless steel wire mesh can be designed to fit a wide range of fixtures and structures, including custom designs.

-

Fully recyclable: Stainless steel wire cable mesh is fully recyclable, making it an environmentally friendly option.

Stainless steel wire rope mesh can be installed both horizontally and vertically, depending on the specific requirements of the project.

The choice of orientation may depend on various factors such as the purpose of the installation, the design of the structure, and the load-bearing capacity of the mesh. In some cases, it may be more practical or visually appealing to install the mesh horizontally, while in others, a vertical installation may be more appropriate.

Horizontal installation of stainless steel wire rope mesh is often used for applications such as safety barriers, decorative cladding, or animal enclosures. It can provide an unobstructed view, while still offering the necessary protection or containment.

Vertical installation, on the other hand, is commonly used for applications such as facade cladding or green wall systems. It can provide a more visually striking appearance and can also offer better support for climbing plants or vegetation.

Ultimately, the decision to install stainless steel wire rope mesh horizontally or vertically will depend on the specific needs and goals of the project, as well as the expertise of the engineers and architects involved in the design and installation process.

Some of the key features of stainless steel wire cable mesh include:

-

High strength and toughness: Stainless steel wire cable mesh is made from high-strength steel wire rope, which gives it excellent strength and durability.

-

Free-angle curving and foldable: Stainless steel wire cable mesh can be curved and folded into various shapes and angles, making it ideal for use in complex structures.

-

Portable and discreet: Stainless steel wire cable mesh is lightweight and easy to transport, and its discreet design makes it suitable for use in a wide range of settings.

Stainless steel wire cable mesh can be used in various applications, including:

-

Above personnel: Stainless steel wire cable mesh can be used to provide overhead protection for personnel working in hazardous environments.

-

On mobile equipment: Stainless steel cable mesh can be used to protect equipment such as crane booms, drill rigs, and shovels from impact and wear.

-

In potential impact zones of mobile equipment: Stainless steel cable mesh can be used to protect structures and fixtures that are located in areas where they may be impacted by mobile equipment.

-

Prone to oxidation and galvanic corrosion: Stainless steel wire cable mesh can be used to protect fixtures and structures that are vulnerable to corrosion.

-

Above essential or expensive equipment: Stainless steel wire cable mesh can be used to protect valuable equipment from damage.

-

In areas difficult to access for maintenance or inspection: Stainless steel cable mesh can be used to protect fixtures and structures that are located in areas that are difficult to access for maintenance or inspection.

-

Items being replaced, maintained, or repaired in situ: Stainless steel wire cable mesh can be used to provide temporary protection for fixtures and structures while they are being replaced, maintained, or repaired in situ.

Ferrule Types Stainless Steel Wire Cable mesh

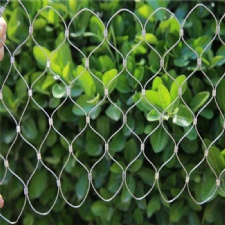

Ferruled mesh is a type of woven mesh that is similar to knotted mesh in terms of its physical properties, such as strength and durability. However, the key difference between the two is in the way that the stainless steel wire ropes are combined.

In ferruled mesh, the wire ropes are combined using small metal sleeves or ferrules that are made of the same grade stainless steel as the wire ropes. The ferrules are crimped onto the wire ropes using specialized tools, which creates a tight and secure connection between the wires.

The use of ferrules in the construction of the mesh allows for a greater degree of flexibility and customization in terms of the mesh size and shape. This is because the ferrules can be placed at different intervals along the wire ropes to create larger or smaller openings in the mesh.

Additionally, because the ferrules are made of the same grade stainless steel as the wire ropes, ferruled mesh offers excellent resistance to corrosion and rust, making it suitable for use in outdoor or marine environments.

Specifications

| Type | Item No.s | Cable Diameter | Mesh Opening | Cable Structure | Normal Break |

|---|---|---|---|---|---|

| Ferruled Type | SL-3212K- | 1/8 inch (3.2mm) | 4.75 x 8.23 inch (120 x 207.8mm) | - | 1,600 lbs. |

| SL-3210K | 1/8 inch (3.2mm) | 4 x 6.9 inch (102 x 176.7mm) | - | 1,600 lbs. | |

| SL-3290K | 1/8 inch (3.2mm) | 3.55 x 6.15 inch (90 x 156mm) | - | 1,600 lbs. | |

| SL-3276K | 1/8 inch (3.2mm) | 3 x 5.2 inch (76 x 131.6mm) | - | 1,600 lbs. | |

| SL-3251K | 1/8 inch (3.2mm) | 2 x 3.46 inch (51 x 88.3mm) | - | 1,600 lbs. | |

| SL-2410K | 3/32 inch (2.4mm) | 4 x 6.9 inch (102 x 176.7mm) | - | 920 lbs. | |

| SL-2490K | 3/32 inch (2.4mm) | 3.55 x 6.15 inch (90 x 156mm) | - | 920 lbs. | |

| SL-2476K | 3/32 inch (2.4mm) | 3 x 5.2 inch (76 x 131.6mm) | - | 920 lbs. | |

| SL-2460K | 3/32 inch (2.4mm) | 2.4 x 4.16 inch (60 x 104mm) | - | 920 lbs. | |

| SL-2451K | 3/32 inch (2.4mm) | 2 x 3.46 inch (51 x 88.3mm) | - | 920 lbs. | |

| SL-2076K | 5/64 inch (2.0mm) | 3 x 5.2 inch (76 x 131.6mm) | - | 676 lbs. | |

| SL-2060K | 5/64 inch (2.0mm) | 2.4 x 4.16 inch (60 x 104mm) | - | 676 lbs. | |

| SL-2051K | 5/64 inch (2.0mm) | 2 x 3.46 inch (51 x 88.3mm) | - | 676 lbs |

Knotted Type Stainless Steel Wire Cable MeshA knotted mesh is a type of woven mesh that is commonly used for various applications, such as safety nets, animal enclosures, and architectural facades. In knotted mesh, the warp and weft wire ropes are interwoven in a plain weave pattern, where each warp wire crosses over and under each weft wire alternately. However, unlike traditional plain weave where the warp and weft wires are not connected to each other, in knotted mesh, the warp and weft wires are twisted and knotted together at every point where they intersect. This creates a much stronger and more stable mesh that can withstand higher loads and stresses. The diameter of the warp and weft wire ropes in knotted mesh is typically the same, which helps to maintain a uniform and consistent appearance. However, in some cases, the diameter of the warp wire may be slightly larger than the weft wire to provide additional strength and support. Overall, knotted mesh is a versatile and durable woven mesh that offers a range of benefits for various applications.

Specifications |

|||||

| Item No.s | Cable diameter | Mesh Opening(W x H) | Cable Structure | ||

| mm | mm | ||||

| SL-4021B | 4.0 | 210 x 210 | 7 x 19 | ||

| SL-4018B | 4.0 | 180 x 180 | 7 x 19 | ||

| SL-4015B | 4.0 | 150 x 150 | 7 x 19 | ||

| SL-4012B | 4.0 | 120 x 120 | 7 x 19 | ||

| SL-3021B | 3.0 | 210 x 210 | 7 x 19 | ||

| SL-3018B | 3.0 | 180 x 180 | 7 x 7 | ||

| SL-3015B | 3.0 | 150 x 150 | 7 x 7 | ||

| SL-2013B | 3.0 | 120 x 120 | 7 x 7 | ||

| SL-3010B | 3.0 | 100 x 100 | 7 x 7 | ||

| SL-3075B | 3.0 | 75 x 75 | 7 x 7 | ||

| SL-2018B | 2.0 | 180 x 180 | 7 x 7 | ||

| SL-2015B | 2.0 | 150 x 150 | 7 x 7 | ||

| SL-2012B | 2.0 | 120 x 120 | 7 x 7 | ||

| SL-2010B | 2.0 | 100 x 100 | 7 x 7 | ||

| SL-2075B | 2.0 | 75 x 75 | 7 x 7 | ||

| SL-2060B | 2.0 | 60 x 60 | 7 x 7 | ||

| SL-2050B | 2.0 | 50 x 50 | 7 x 7 | ||

| SL-1510B | 1.5 | 100 x 100 | 7 x 7 | ||

| SL-1575B | 1.5 | 75 x 75 | 7 x 7 | ||

| SL-1560B | 1.5 | 60 x 60 | 7 x 7 | ||

| SL-1550B | 1.5 | 50 x 50 | 7 x 7 | ||

When it comes to packaging stainless steel wire cable mesh, it's important to ensure that the material is protected from damage during transit and storage.

Here are some packaging details for stainless steel wire cable mesh:

-

Inner packing: The stainless steel wire cable mesh should be wrapped in water-proof cloth to protect it from moisture and damage.

-

Outer packing: The mesh should be packed in wooden cases to provide additional protection during shipping. The wooden cases should be sturdy and securely fastened to prevent any movement during transit.

-

Bundling: The stainless steel ferrule rope mesh can be fixed into a bundle with strings to prevent it from becoming tangled or damaged.

-

Customized packing: The packaging can be customized according to the customer's requirements, such as adding additional layers of protection or labeling the packaging for easy identification.

In summary, proper packaging of stainless steel wire cable mesh is essential to ensure that it arrives at its destination in good condition. The use of water-proof cloth, wooden cases, and bundling with strings are all effective ways to protect the mesh during transit and storage.

Stainless steel wire cable mesh can be used for a variety of applications, including as a safety barrier, decorative mesh, and animal enclosure. When it comes to mounting accessories for stainless steel wire cable mesh, there are a few options to consider:

-

Cable Ties: Cable ties are an inexpensive and easy way to attach stainless steel wire cable mesh to a variety of surfaces. They are available in a variety of sizes and strengths to match the needs of your specific application.

-

Clips: Clips are another option for attaching stainless steel wire cable mesh to a surface. They come in a variety of shapes and sizes, including J-clips, S-clips, and U-clips, and can be attached using screws or rivets.

-

Eye Bolts: Eye bolts are a good option if you need to suspend the stainless steel wire cable mesh from above. They can be attached to a ceiling or other overhead surface using a variety of hardware, including screws, anchors, and chains.

-

Tensioning Systems: Tensioning systems are used to tighten the stainless steel wire cable mesh to create a taut and secure barrier. These systems typically consist of turnbuckles, wire rope grips, and other hardware that allows you to adjust the tension of the cable mesh.

Overall, the choice of mounting accessories for stainless steel wire cable mesh will depend on the specific application and the surface to which it is being attached. It is important to choose the right accessories to ensure that the cable mesh is securely mounted and can perform its intended function.

Boss Metal And Plastic Co Limited

Boss Metal And Plastic Co Limited