Stainless steel rope wire mesh is a type of wire mesh made from stainless steel wire ropes that are woven together to create a mesh structure. This type of mesh is also known as wire cable mesh or wire rope netting.

Stainless steel rope wire mesh is commonly used in various applications where high strength, durability, and corrosion resistance are required. It is commonly used in architectural applications such as building facades, balustrades, and safety barriers. It is also used in zoological and aquarium zoo mesh, as well as in industrial applications such as machinery guards and conveyor belts.

The mesh is made by weaving the stainless steel wire ropes together using a specialized weaving technique. The resulting mesh has a unique structure that provides strength and durability, as well as a visually appealing appearance. The size of the mesh can be customized to fit specific project requirements.

Stainless steel rope wire mesh is resistant to corrosion, making it ideal for use in outdoor environments or in applications where exposure to water or chemicals is likely. It is also easy to maintain and clean, making it a popular choice for applications that require hygienic conditions.

Overall, stainless steel rope wire mesh is a versatile and durable material that is well-suited for a wide range of applications.

There are several other installation accessories that are commonly used with stainless steel rope wire mesh:

- Turnbuckles: These are devices used to adjust the tension of the wire ropes in the mesh.

- Eyebolts: These are used to anchor the mesh to the structure or frame it is being installed on.

- Clamps: These are used to secure the mesh to the structure or frame and are available in different shapes and sizes.

- Connectors: These are used to connect separate sections of mesh together.

- Support cables: These are additional cables that can be used to provide additional support to the mesh and can be attached to the structure or frame.

It is important to note that while stainless steel rope wire mesh does not require maintenance after installation, it is important to periodically inspect it to ensure that it is still secure and in good condition. Any damaged or worn components should be repaired or replaced promptly to ensure the continued safety and functionality of the mesh.

Specifications

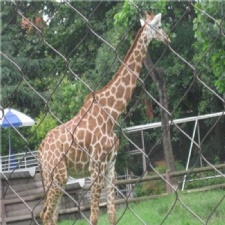

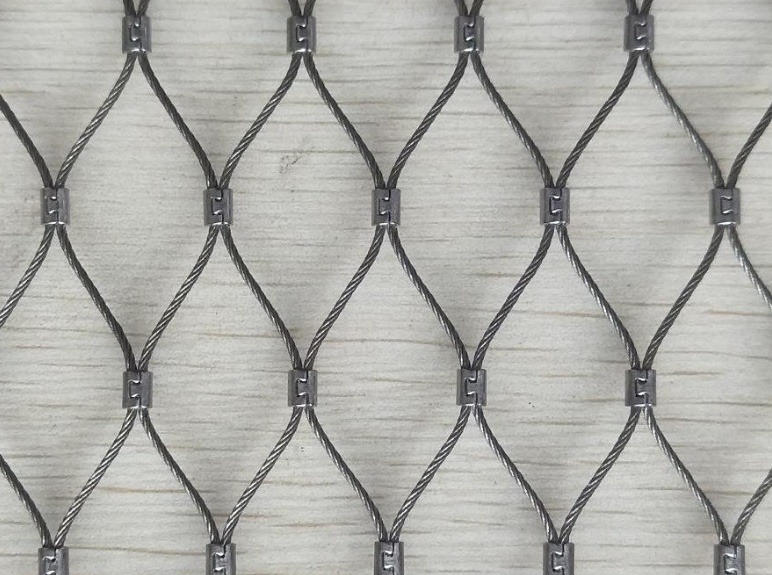

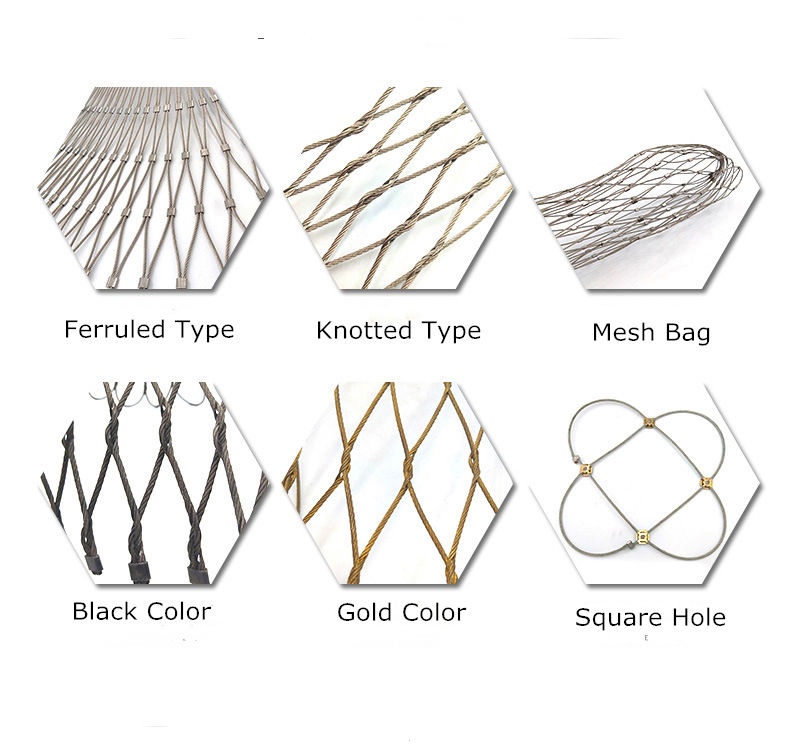

Flexible stainless steel cable mesh is a type of wire mesh that is made from stainless steel wire rope. The rope is constructed in either a 7 x 7 or 7 x 19 pattern and is made from either AISI 304 or 316 material. The mesh can be woven by hand in an inter-woven pattern or using ferrules. The knotted type refers to the inter-woven mesh that has knots at each intersection of the wire ropes. This type of mesh is commonly used for architectural purposes, such as balustrades, facades, and safety nets, as well as for animal enclosures and aviaries. It is known for its strength, durability, and flexibility.

Code- knotted |

Rope Construction |

Rope Diameter |

Opening Size |

Breaking Force |

||

|

Inch |

mm |

Inch |

mm |

KN |

||

|

BM-01 |

7 × 19 |

1/8 |

3.2 |

4.7" × 4.7." |

120 × 120 |

7.38 |

|

BM-02 |

7 × 19 |

1/8 |

3.2 |

4" × 4." |

102 × 102 |

7.38 |

|

BM-03 |

7 × 19 |

1/8 |

3.2 |

3.6" × 3.6." |

90 × 90 |

7.38 |

|

BM-04 |

7 × 19 |

1/8 |

3.2 |

3" × 3." |

76 × 76 |

7.38 |

|

BM-05 |

7 × 19 |

1/8 |

3.2 |

2" × 2." |

51 × 51 |

7.38 |

|

BM-06 |

7 × 7 |

3/32 |

2.4 |

4" × 4." |

102 × 102 |

4.18 |

|

BM-07 |

7 × 7 |

3/32 |

2.4 |

3.6" × 3.6." |

90 × 90 |

4.18 |

|

BM-08 |

7 × 7 |

3/32 |

2.4 |

3" × 3." |

76 × 76 |

4.18 |

|

BM-09 |

7 × 7 |

3/32 |

2.4 |

2.4" × 2.4." |

60 × 60 |

4.18 |

|

BM-10 |

7 × 7 |

3/32 |

2.4 |

2" × 2." |

51 × 51 |

4.18 |

|

BM-11 |

7 × 7 |

5/64 |

2 |

3" × 3." |

76 × 76 |

3.17 |

|

BM-12 |

7 × 7 |

5/64 |

2 |

2.4" × 2.4." |

60 × 60 |

3.17 |

|

BM-13 |

7 × 7 |

5/64 |

2 |

2" × 2." |

51 × 51 |

3.17 |

|

BM-14 |

7 × 7 |

5/64 |

2 |

1.5" × 1.5" |

38 × 38 |

3.17 |

|

BM-15 |

7 × 7 |

1/16 |

1.6 |

3" × 3." |

76 × 76 |

2.17 |

|

BM-16 |

7 × 7 |

1/16 |

1.6 |

2" × 2." |

51 × 51 |

2.17 |

|

BM-17 |

7 × 7 |

1/16 |

1.6 |

1.5" × 1.5" |

38 × 38 |

2.17 |

|

BM-18 |

7 × 7 |

1/16 |

1.6 |

1.2" × 1.2" |

30 × 30 |

2.17 |

|

BM-19 |

7 × 7 |

1/16 |

1.6 |

1" × 1." |

25 × 25 |

2.17 |

|

BM-20 |

7 × 7 |

3/64 |

1.2 |

2" × 2." |

51 × 51 |

1.22 |

|

BM-21 |

7 × 7 |

3/64 |

1.2 |

1.5" × 1.5" |

38 × 38 |

1.22 |

|

BM-22 |

7 × 7 |

3/64 |

1.2 |

1.2" × 1.2" |

30 × 30 |

1.22 |

|

BM-23 |

7 × 7 |

3/64 |

1.2 |

1" × 1." |

25 × 25 |

1.22 |

|

BM-24 |

7 × 7 |

3/64 |

1.2 |

0.8" × 0.8" |

20 × 20 |

1.22 |

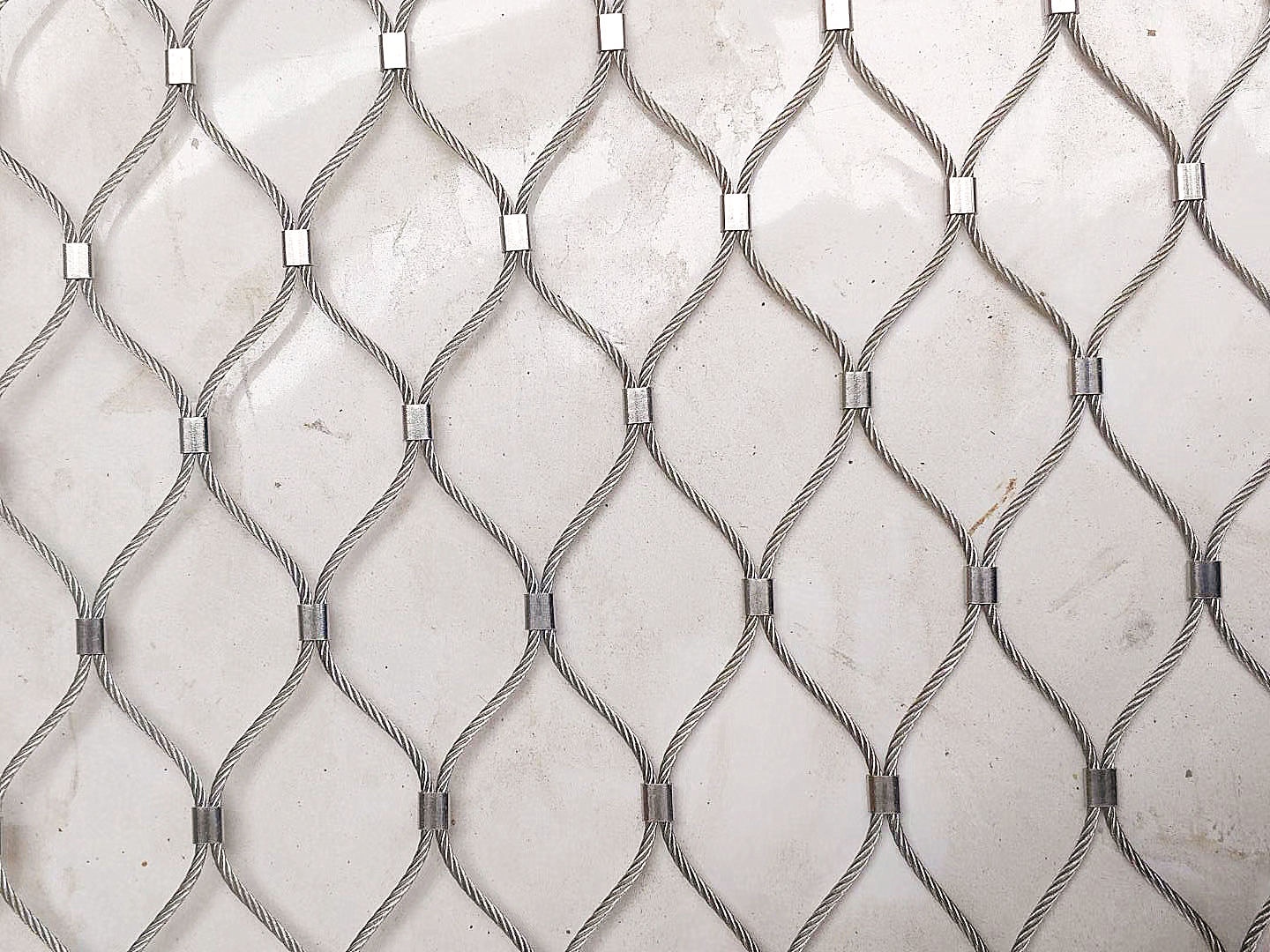

Stainless steel rope wire mesh (Ferrule type) is a versatile and durable solution for a wide range of applications in various industries. Ferrule type mesh is a popular choice for balustrades on bridges and staircases, large barrier fences, and building facade trellis systems due to its strength and flexibility.

Types

- The ferrule type series is divided into various materials, including aluminium alloy mesh, stainless steel mesh, tinned copper mesh, and nickel-copper mesh. Each type of mesh is designed to meet specific requirements and provide unique benefits.

- Stainless steel ferrule mesh is the most popular choice due to its excellent resistance to corrosion, high strength, and long-lasting durability. It is widely used in architectural applications such as balustrades, facades, and green wall systems. The stainless steel ferrule mesh is available in various sizes and shapes to meet different design and application requirements.

- Aluminium alloy ferrule mesh is another popular option due to its lightweight and high strength. It is commonly used in tension structures, decorative screens, and cladding systems. The aluminium alloy ferrule mesh is available in different colours and finishes to match specific design requirements.

- Tinned copper ferrule mesh is ideal for applications requiring excellent electrical conductivity and resistance to corrosion. It is commonly used in electrical grounding systems, EMI/RFI shielding, and industrial filtration systems.

- Nickel-copper ferrule mesh is highly resistant to corrosion and is often used in marine and offshore applications, as well as in chemical and petrochemical processing. It is also commonly used in architectural applications requiring a high level of corrosion resistance.

- In conclusion, flexible stainless steel cable mesh (Ferrule type) is a versatile and durable solution for a wide range of applications in various industries. The choice of ferrule material depends on the specific requirements of the application. Stainless steel, aluminium alloy, tinned copper, and nickel-copper are the most commonly used materials in the ferrule type series.

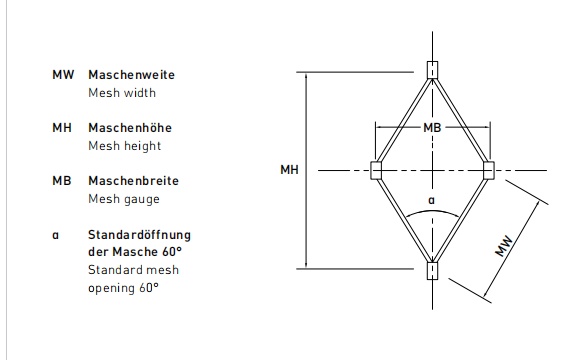

Technical Informations

Code |

Rope Construction |

Rope Diameter |

Aperture |

Breaking Force |

|

|

Inch |

mm |

mm |

kN |

||

|

BM-01 |

7 × 19 |

1/8 |

3.2 |

120 × 208 |

7.38 |

|

BM-02 |

7 × 19 |

1/8 |

3.2 |

100 × 173 |

7.38 |

|

BM-03 |

7 × 19 |

1/8 |

3.2 |

90 × 156 |

7.38 |

|

BM-04 |

7 × 7 |

3/32 |

2.4 |

100 × 173 |

4.18 |

|

BM-05 |

7 × 7 |

3/32 |

2.4 |

90 × 156 |

4.18 |

|

BM-06 |

7 × 7 |

3/32 |

2.4 |

80 × 139 |

4.18 |

|

BM-07 |

7 × 7 |

3/32 |

2.4 |

70 × 121 |

4.18 |

|

BM-08 |

7 × 7 |

5/64 |

2 |

100 × 173 |

3.17 |

|

BM-09 |

7 × 7 |

5/64 |

2 |

90 × 156 |

3.17 |

|

BM-10 |

7 × 7 |

5/64 |

2 |

80 × 139 |

3.17 |

|

BM-11 |

7 × 7 |

5/64 |

2 |

70 × 121 |

3.17 |

|

BM-12 |

7 × 7 |

1/16 |

1.6 |

80 × 139 |

2.17 |

|

BM-13 |

7 × 7 |

1/16 |

1.6 |

70 × 121 |

2.17 |

|

BM-14 |

7 × 7 |

1/16 |

1.6 |

60 × 104 |

2.17 |

|

BM-15 |

7 × 7 |

1/16 |

1.6 |

51 × 87 |

2.17 |

|

BM-16 |

7 × 7 |

3/64 |

1.2 |

80 × 139 |

1.22 |

|

BM-17 |

7 × 7 |

3/64 |

1.2 |

60 × 104 |

1.22 |

|

BM-18 |

7 × 7 |

3/64 |

1.2 |

50 × 87 |

1.22 |

|

BM-19 |

7 × 7 |

3/64 |

1.2 |

40 × 69 |

1.22 |

Packing

When it comes to packaging stainless steel rope wire mesh, the method used can depend on various factors, such as the size and quantity of the order, as well as the shipping destination and the customer's specific requirements.

For large orders of stainless steel rope wire mesh, it is common to package the mesh in wooden boxes. This is because wooden boxes are sturdy and can provide adequate protection during shipping, especially when the order is being transported over long distances. Additionally, wooden boxes can be stacked on top of each other, which can help optimize space during shipping.

On the other hand, for smaller quantity orders, it may be more cost-effective to use PP bags for packaging. PP bags are lightweight and easy to handle, making them a convenient option for smaller orders. Additionally, they can be easily transported and stored, which can help reduce shipping costs.

In any case, it is important to ensure that the packaging used provides adequate protection to the stainless steel rope wire mesh during shipping. This can help prevent damage to the mesh and ensure that it arrives at the destination in good condition.

Boss Metal And Plastic Co Limited

Boss Metal And Plastic Co Limited