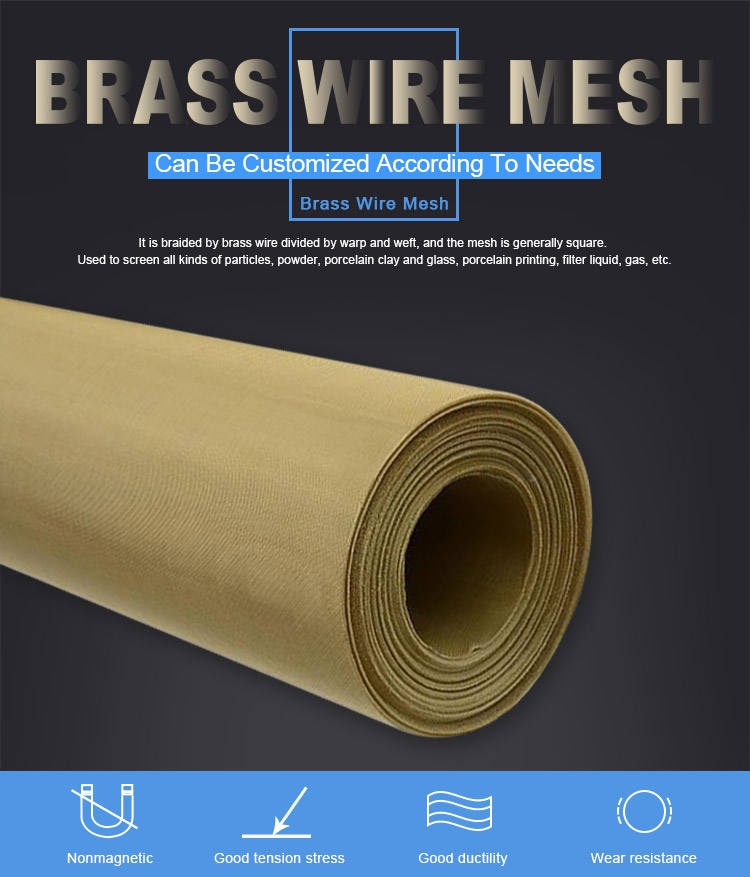

Brass wire mesh is a type of wire mesh that is made from brass wire. Brass is an alloy of copper and zinc and is known for its excellent durability, corrosion resistance, and electrical conductivity. They are commonly used in a variety of applications, such as filtration, sieving, and decorative purposes.

The wire mesh is made by weaving together strands of brass wire in a particular pattern, such as plain weave, twill weave, or dutch weave. The wire diameter and mesh size can vary depending on the intended use of the brass wire mesh. Brass wire mesh can be produced in a wide range of sizes, from small filters and screens to large industrial applications.

Weave Types

-

Plain weave is a basic weaving technique where the warp and weft yarns are interlaced at a 90 degree angle, with each weft thread passing alternately over and under each warp thread. This creates a simple, uniform pattern that is characterized by a mesh with a consistent size. The thickness of the weft yarns is generally the same as the warp yarns.

-

Twill weaving is a type of weaving where the weft yarns are passed over and under two or more warp yarns, creating a diagonal pattern on the fabric. This creates a distinctive look that is often associated with denim and other sturdy fabrics. Twill weaves are known for their durability and abrasion resistance, making them ideal for clothing and other applications where strength and durability are important.

The production process of brass wire mesh typically involves the following steps:

-

Wire drawing: The first step is to draw the brass wire through a series of dies to reduce its diameter and improve its strength and uniformity.

-

Annealing: After wire drawing, the brass wire is annealed to improve its ductility and workability. Annealing involves heating the wire to a specific temperature and then cooling it slowly to relieve any internal stresses and improve its mechanical properties.

-

Weaving: The brass wire is then woven on a loom to create the mesh pattern. The weaving process involves interlacing the warp and weft wires together in an alternating pattern to create a strong, flexible mesh.

-

Inspection: Once the mesh has been woven, it is inspected to ensure that it meets the required specifications for size, shape, and strength.

-

Finishing: Finally, the brass wire mesh is finished by cutting it to size, cleaning it to remove any debris or residue, and packaging it for shipment or storage.

Some common uses of brass wire mesh include:

-

Filtration: Brass wire mesh is used as a filter to separate particles from liquids and gases. It can be used in water treatment plants, oil refineries, and chemical processing plants.

-

Sieving: Brass wire mesh is used to separate and classify materials based on size. It is commonly used in the food industry to sift flour and other dry ingredients.

-

Decorative: Brass wire mesh is used in architecture and interior design for decorative purposes, such as railing infill panels, wall cladding, and room dividers.

-

Electrical conductivity: Brass wire mesh can be used in electrical applications where a high level of conductivity is required. It is commonly used in radio frequency shielding, grounding, and electrical contact applications.

Brass wire mesh is a versatile material with a wide range of applications. Its unique properties make it a popular choice for various industries, including aerospace, automotive, construction, and manufacturing.

-

Filtration: Brass wire mesh is commonly used as a filter in industrial and laboratory settings. It can be used to filter liquids, gases, and particulate matter.

-

Sieving: Brass wire mesh is used in sieving applications to separate different sizes of particles or to remove impurities from materials.

-

Decorative: wire mesh is used in architectural and decorative applications, such as in window screens, room dividers, and decorative panels.

-

Electrical: wire mesh is used as a conductor in some electrical applications, such as in radio frequency interference (RFI) shielding.

-

Printing: wire mesh is used in printing applications, such as in screen printing, to create detailed and precise prints.

-

Jewelry: Brass wire mesh can be used in jewelry making to create unique and textured pieces.

-

Insect screens: Brass wire mesh can be used as an insect screen to prevent insects from entering buildings or outdoor spaces.

-

Chemical processing: Brass wire mesh is used in chemical processing applications, such as in distillation and refining processes.

-

Food processing: Brass wire mesh is used in food processing applications, such as in sieving and filtering processes.

Overall, brass wire mesh is a versatile material that can be used in a wide range of applications due to its strength, durability, and corrosion resistance.

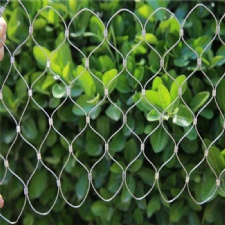

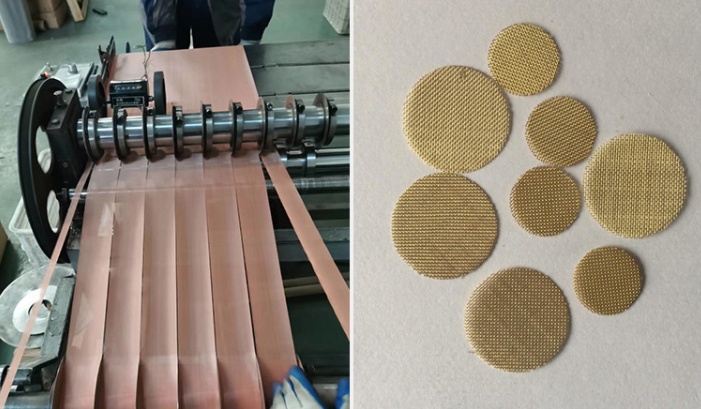

Physical picture

Brass Wire Mesh Specification

Part-1 brass wire mesh

|

Product code |

Mesh/inch |

Wire diameter |

Opening |

Open area |

|

|

mm |

inch |

mm |

|||

|

BMP-214 |

2 |

2.030 |

0.800 |

10.67 |

70 |

|

BMP-215 |

2 |

1.800 |

0.072 |

10.90 |

73 |

|

BMP-216 |

2 |

1.600 |

0.063 |

11.10 |

76 |

|

BMP-316 |

3 |

1.600 |

0.063 |

6.87 |

65 |

|

BMP-418 |

4 |

1.194 |

0.047 |

5.16 |

66 |

|

BMP-520 |

5 |

0.910 |

0.035 |

4.17 |

67 |

|

BMP-822 |

8 |

0.711 |

0.028 |

2.46 |

60 |

|

BMP-621 |

6 |

0.800 |

0.032 |

3.43 |

66 |

|

BMP-622 |

6 |

0.711 |

0.028 |

3.52 |

69 |

|

BMP-823 |

8 |

0.610 |

0.024 |

2.57 |

65 |

|

BMP-824 |

8 |

0.559 |

0.022 |

2.62 |

68 |

|

BMP-1023 |

10 |

0.635 |

0.025 |

1.90 |

56 |

|

BMP-1024 |

10 |

0.559 |

0.022 |

1.98 |

61 |

|

BMP-1025 |

10 |

0.508 |

0.020 |

2.03 |

64 |

|

BMP-1224 |

12 |

0.584 |

0.023 |

1.47 |

52 |

|

BMP-1226 |

12 |

0.457 |

0.018 |

1.66 |

61 |

|

BMP-1425 |

14 |

0.500 |

0.020 |

1.31 |

52 |

|

BMP-1426 |

14 |

0.457 |

0.018 |

1.36 |

56 |

|

BMP-1427 |

14 |

0.417 |

0.016 |

1.40 |

59 |

|

BMP-1626 |

16 |

0.457 |

0.018 |

1.12 |

50 |

|

BMP-1629 |

16 |

0.345 |

0.014 |

1.24 |

61 |

|

BMP-1630 |

16 |

0.315 |

0.012 |

1.27 |

64 |

|

BMP-1826 |

18 |

0.45 |

0.018 |

0.96 |

46 |

|

BMP-1827 |

18 |

0.432 |

0.017 |

0.97 |

48 |

Part -2 brass wire mesh

|

bmp-1830 |

18 |

0.315 |

0.012 |

1.10 |

|

bmp-2030 |

20 |

0.315 |

0.012 |

0.96 |

|

bmp-2032 |

20 |

0.247 |

0.011 |

0.88 |

|

bmp-2230 |

22 |

0.315 |

0.012 |

0.84 |

|

bmp-2430 |

24 |

0.315 |

0.012 |

0.74 |

|

bmp-2631 |

26 |

0.295 |

0.012 |

0.68 |

|

bmp-2831 |

28 |

0.295 |

0.012 |

0.61 |

|

bmp-3027 |

20 |

0.407 |

0.016 |

0.86 |

|

bmp-3030 |

30 |

0.305 |

0.012 |

0.53 |

|

bmp-3032 |

30 |

0.247 |

0.011 |

0.57 |

|

bmp-3034 |

30 |

0.234 |

0.009 |

0.61 |

|

bmp-3233 |

32 |

0.254 |

0.010 |

0.54 |

|

bmp-3434 |

34 |

0.234 |

0.009 |

0.51 |

|

bmp-3634 |

36 |

0.234 |

0.009 |

0.47 |

|

bmp-3835 |

38 |

0.213 |

0.008 |

0.46 |

|

bmp-4031 |

40 |

0.254 |

0.010 |

0.38 |

|

bmp-4036 |

40 |

0.193 |

0.008 |

0.44 |

|

bmp-4038 |

40 |

0.152 |

0.006 |

0.46 |

|

bmp-4236 |

42 |

0.193 |

0.008 |

0.41 |

|

bmp-4437 |

44 |

0.173 |

0.007 |

0.40 |

|

bmp-4637 |

46 |

0.173 |

0.007 |

0.38 |

|

bmp-4837 |

48 |

0.173 |

0.007 |

0.38 |

|

bmp-5032 |

50 |

0.230 |

0.009 |

0.28 |

|

bmp-5037 |

50 |

0.173 |

0.007 |

0.34 |

|

bmp-5039 |

50 |

0.132 |

0.005 |

0.38 |

|

bmp-6036 |

60 × 50 |

0.193 |

0.008 |

- |

|

bmp-6037a |

60 × 50 |

0.173 |

0.007 |

- |

Here are some more details on the features of brass wire mesh:

-

Abrasion resistance: Brass wire mesh has good abrasion resistance, making it ideal for use in applications where it will be exposed to wear and tear.

-

Corrosion resistance: Brass wire mesh is highly resistant to corrosion, making it suitable for use in harsh environments.

-

High temperature and spark resistance: Brass wire mesh can withstand high temperatures and is spark-resistant, making it suitable for use in applications where heat and sparks are present.

-

Acid and alkali resistance: wire mesh is resistant to acids and alkalis, making it suitable for use in chemical processing applications.

-

Durable and good elasticity: wire mesh is durable and has good elasticity, allowing it to withstand heavy use without breaking or losing its shape.

-

Tensile strength: wire mesh has good tensile strength, making it suitable for use in applications where strength and durability are important.

-

Light, air, and liquid permeability: Brass wire mesh allows light, air, and liquids to pass through, making it suitable for use in filtration and sieving applications.

-

Atmospheric discoloration: wire mesh may discolor over time due to atmospheric conditions, which may be undesirable in some applications.

-

Not suitable for saltwater applications: Brass wire mesh is not recommended for use in saltwater environments, as it may corrode over time.

-

Easy to clean and install: Brass wire mesh is easy to clean and install, making it a convenient choice for many applications.

-

Lower electrical and heat conductivity: Brass wire mesh has lower electrical and heat conductivity than copper mesh cloth, making it suitable for applications where these properties are not critical.

Part-3 brass wire mesh specification

|

BMP-6034 |

60 |

0.190 |

0.008 |

0.23 |

30 |

|

BMP-6037b |

60 |

0.173 |

0.007 |

0.25 |

35 |

|

BMP-6040 |

60 |

0.122 |

0.005 |

1.30 |

83 |

|

BMP-7039 |

70 |

0.132 |

0.005 |

0.23 |

40 |

|

BMP-7041 |

70 |

0.112 |

0.004 |

0.25 |

48 |

|

BMP-8035 |

80 |

0.140 |

0.006 |

0.18 |

31 |

|

BMP-8040 |

80 |

0.122 |

0.005 |

0.20 |

38 |

|

BMP-8042 |

80 |

0.102 |

0.004 |

0.22 |

46 |

|

BMP-9041 |

90 |

0.112 |

0.004 |

0.17 |

36 |

|

BMP-9043 |

90 |

0.091 |

0.004 |

0.19 |

46 |

|

BMP-10036 |

100 |

0.114 |

0.005 |

0.14 |

30 |

|

BMP-10042 |

100 |

0.102 |

0.004 |

0.15 |

36 |

|

BMP-10043 |

100 |

0.091 |

0.004 |

0.16 |

41 |

|

BMP-12043 |

120 × 108 |

0.091 |

0.004 |

- |

- |

|

BMP-12044 |

120 |

0.081 |

0.003 |

0.13 |

38 |

|

BMP-12045 |

120 |

0.071 |

0.003 |

0.14 |

44 |

|

BMP-14045 |

140 |

0.071 |

0.003 |

0.11 |

37 |

|

BMP-14046 |

140 |

0.061 |

0.002 |

0.12 |

44 |

|

BMP-15046 |

150 |

0.061 |

0.002 |

0.11 |

41 |

|

BMP-16046 |

160 |

0.061 |

0.002 |

0.10 |

38 |

|

BMP-18046 |

180 |

0.061 |

0.002 |

0.08 |

32 |

|

BMP-18047 |

180 |

0.051 |

0.002 |

0.09 |

41 |

|

BMP-20047 |

200 |

0.051 |

0.002 |

0.08 |

36 |

|

* brass wire mesh size and wire diameter can be customized according to particular needs. |

|||||

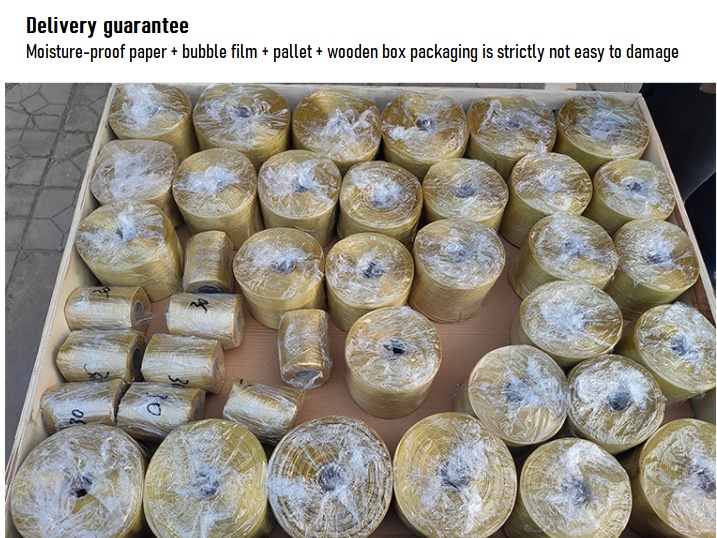

Packing

Brass wire mesh is typically packaged in plastic film to protect it from moisture and other environmental factors during shipping and storage. The mesh is then placed in a carton box or wooden case for added protection and ease of handling. The packaging also helps to prevent any damage to the mesh during transportation and ensures that it arrives at its destination in good condition. The size and type of packaging used may vary depending on the size and quantity of the brass wire mesh being shipped.

FAQ

- Are you factory/manufacturer or trader? We are direct factory who owns production lines and workers. Everything is flexible and there is no need to worry about extra charges by the middle man or trader.

- Which countries do you export to? Our goods are mainly exported to Australia, Canada, UK, USA, Germany, Thailand,South Korea and so on.

- Can I get free samples? If the sample is available, yes, can be free. If unavailable, need to customize.

- What is your minimum order quantity?Actually there is no MOQ for our products. But usually we recommend a quantity based on the price which is easy to accept.

- Which payment method you can accept? Generally we adopt T/T, LC, Western Union, PayPal, Escrow and Money Gram.

- What is your lead time for production? It depends on the specific product and quantity. Generally, our lead time is around 15-30 days after receiving the deposit or payment.

- Can you customize the product according to my requirements? Yes, we have a professional team who can customize the product according to your specific requirements, such as size, shape, material, and color.

- What is your quality control process? We have a strict quality control process in place to ensure that every product meets our high standards. This includes inspection of raw materials, in-process inspection during production, and final inspection before shipment.

- What is your warranty policy? We offer a warranty for our products, typically ranging from 1 to 5 years depending on the product and its intended use. Any defects or issues caused by our manufacturing process will be covered by the warranty.

- What is your after-sales service? We have a dedicated after-sales service team to provide support and assistance to our customers. If you have any issues or questions about our products, we are always available to help.

Boss Metal And Plastic Co Limited

Boss Metal And Plastic Co Limited