folding wire mesh containers, also known as a collapsible wire mesh container or a foldable wire mesh container, is a type of industrial storage container made from welded or woven wire mesh. As the name suggests, these containers can be easily folded or collapsed when not in use, which helps to save storage space and reduce shipping costs.

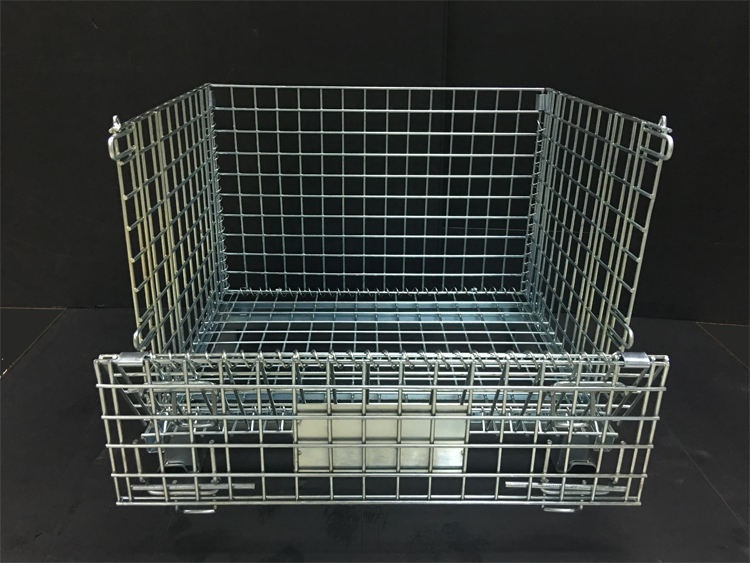

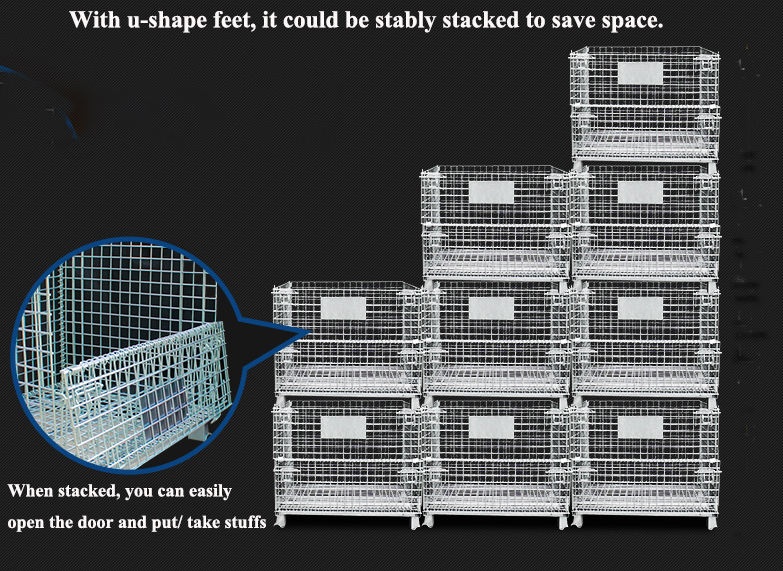

wire mesh containers are typically designed with hinged or removable gates on one or more sides, which allows for easy access to the contents of the container. They are also stackable, which means they can be safely stacked on top of each other to maximize storage space.

One of the main advantages of wire mesh containers is their versatility. They can be used to store and transport a wide range of goods, from small parts and components to larger items like machinery and equipment. They are also commonly used in the automotive industry to store and transport auto parts and accessories.

Folding wire mesh containers are made from high-quality steel wire that is strong and durable, yet lightweight and easy to handle. They are also resistant to rust and corrosion, which makes them ideal for use in damp or humid environments.

Overall, folding wire mesh containers are a popular and cost-effective storage solution that can help to improve efficiency and productivity in a wide range of industries.

Folding wire mesh containers, also known as wire mesh baskets, are used for storage, transportation, and handling of various materials. The specifications of these containers may vary based on the intended use and manufacturer, but some common specifications are as follows:

-

Size: Folding wire mesh containers come in a range of sizes, from small to large. The size of the container will depend on the application and the amount of material to be stored or transported.

-

Capacity: The capacity of the container refers to the maximum weight it can hold. This will vary based on the size and design of the container.

-

Wire gauge: The wire gauge of the container refers to the thickness of the wire used to make the mesh. A thicker wire gauge will make the container stronger and more durable.

-

Mesh size: The mesh size of the container refers to the size of the openings in the wire mesh. This will determine what type of materials can be stored or transported in the container.

-

Finish: The finish of the container can be galvanized or powder-coated. Galvanized containers are more resistant to rust and corrosion, while powder-coated containers can be customized to match the colors of the company or product.

-

Stacking capability: wire mesh containers should be designed to stack securely when not in use to maximize storage space.

-

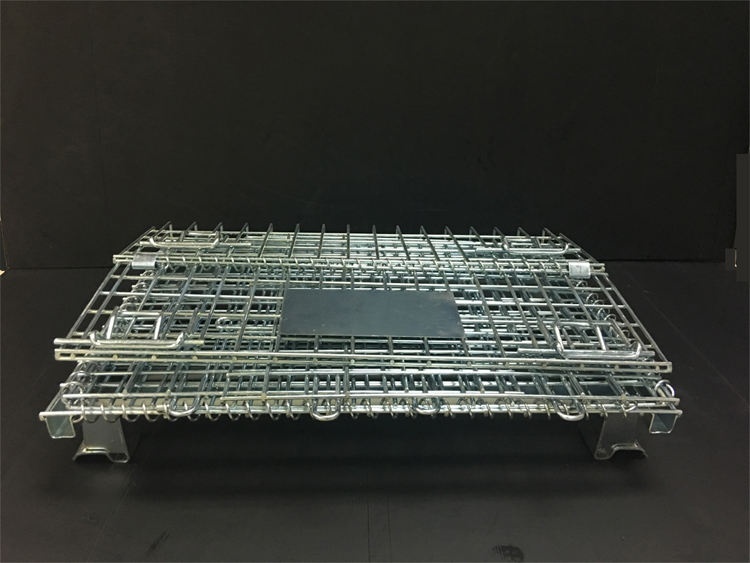

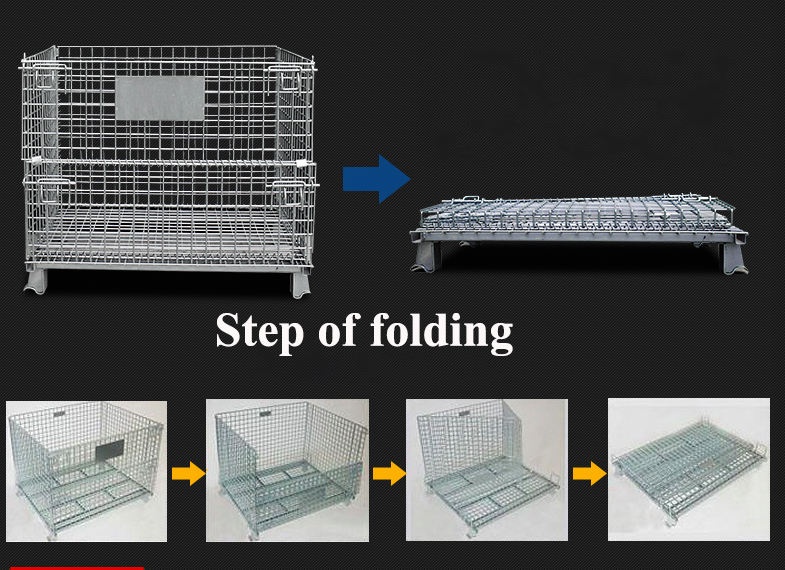

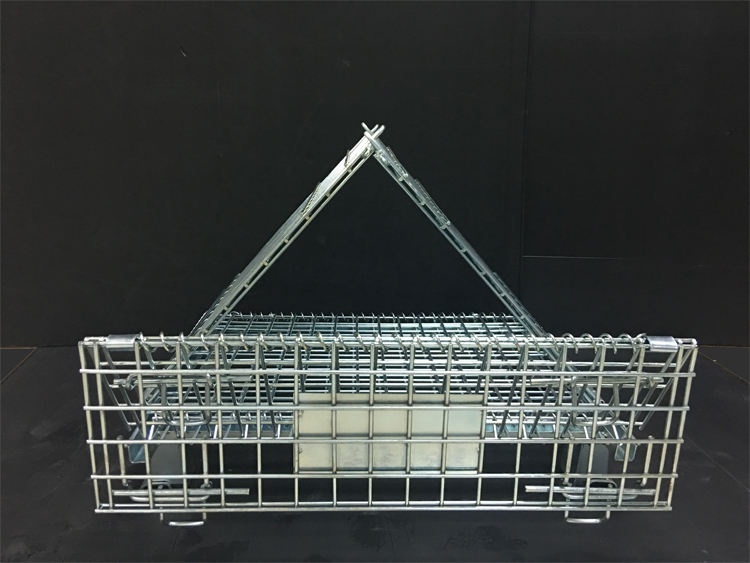

Collapsible: Folding wire mesh containers should be collapsible for easy storage and transportation when not in use.

-

Weight: The weight of the container will depend on the size, wire gauge, and other specifications. A lighter container may be easier to handle and transport, while a heavier container may be more durable and sturdy.

Folding Effect & Stacking Effect folding wire mesh container

|

|

|

|

|

|

Standard Specification |

||||||

|

Model Folding Wire Mesh Containers |

External Size (LxDxH mm) |

Internal Size (LxDxH mm) |

Wire Dia. (mm) |

Grid (mm) |

Weight (kg) |

Loading (kg) |

|

A1 |

800*600*640 |

750*550*500 |

5.6 |

50*50 |

27 |

700 |

|

A2 |

5.8 |

28 |

800 |

|||

|

B1 |

1000*800*840 |

950*750*700 |

5.6 |

50*50 |

42 |

1000 |

|

B2 Folding Wire Mesh Containers |

5.8 |

44 |

1200 |

|||

|

C1 |

1200*1000*890 |

1150*950*750 |

5.6 |

50*50 |

56 |

1300 |

|

C2 |

5.8 |

58 |

1500 |

|||

|

C3 |

5.6 |

50*100 |

48 |

800 |

||

|

C4 |

5.8 |

50 |

1000 |

|||

|

Folding Wire Mesh Containers Material |

Steel Q235 |

|||||

|

Available |

Top Lid / Wheels / Hollow Sheet / Bar Runner / Forklift / Inner divider |

|||||

|

Finish |

Zinc / Hot dipped galvanized / Cold galvanized / Powder coating |

|||||

|

Remark |

Customized or OEM support |

|||||

The production process for folding wire mesh containers typically involves the following steps:

-

Material chooseion: The first step is to choose the appropriate wire mesh material for the containers. This may depend on the specific application and the required strength, durability, and resistance to corrosion.

-

Cutting: The wire mesh is then cut into the required sizes and shapes using a cutting machine.

-

Welding: The wire mesh pieces are then welded together using spot welding or resistance welding techniques to create the container frame.

-

Forming: The frame is then shaped into the desired container shape using a bending machine. This may involve several rounds of bending and shaping to ensure a precise fit.

-

Surface treatment: Depending on the application and desired finish, the wire mesh container may undergo a surface treatment such as galvanizing, powder coating, or painting to provide additional protection against corrosion.

-

Assembly: The final step is to assemble the wire mesh container by attaching any necessary accessories or components such as handles, hinges, or lids.

-

Quality control: Throughout the production process, quality control measures are in place to ensure that the finished wire mesh containers meet the required specifications and standards.

-

Packaging: Once the wire mesh containers are completed and have passed quality control, they are typically packaged and shipped to the customer for use

Folding wire mesh containers are used in a variety of industries for storage, transportation, and handling of various materials. Some common industries and applications where wire mesh containers are required include:

-

Agriculture: Folding wire mesh containers are used in the agriculture industry for storage and transportation of fruits, vegetables, and other crops.

-

Automotive: wire mesh containers are used in the automotive industry for storage and transportation of parts, engines, and other components.

-

Construction: wire mesh containers are used in the construction industry for storage and transportation of building materials such as bricks, blocks, and steel.

-

Manufacturing: wire mesh containers are used in the manufacturing industry for storage and transportation of raw materials and finished products.

-

Retail: wire mesh containers are used in retail stores for storage and display of merchandise.

-

Logistics: wire mesh containers are used in logistics and supply chain management for storage and transportation of goods and materials.

-

Warehousing: Folding wire mesh containers are used in warehouses for storage and organization of inventory.

Overall, folding wire mesh containers are a versatile solution for storage, transportation, and handling of various materials across a range of industries.

Photo

wire mesh containers are widely used in various industries for their versatility, durability, and ease of use. Some common applications of folding wire mesh containers include:

|

|

|

|

|

|

|

-

Material handling and storage: Folding wire mesh containers are commonly used for storage and transport of materials such as automotive parts, hardware, textiles, and food products.

-

Retail display: Folding wire mesh containers are also used in retail stores for displaying merchandise such as clothing, shoes, and accessories.

-

Agriculture: wire mesh containers are used in the agriculture industry for storing and transporting fruits, vegetables, and other produce.

-

Warehousing: wire mesh containers are used in warehouses for organizing and storing goods, and for facilitating the movement of goods throughout the supply chain.

-

Recycling: wire mesh containers are used in the recycling industry for collecting and sorting recyclable materials.

-

Construction: wire mesh containers are used in the construction industry for storing and transporting tools, equipment, and materials such as bricks, tiles, and lumber.

-

Military and defense: Folding wire mesh containers are used in military and defense applications for transport and storage of supplies and equipment.

Overall, folding wire mesh containers are a versatile and durable solution for a wide range of applications in various industries.

Packing and Loading folding wire mesh container

Plastic banding & Stretch film wrapped

easy loading and unloading with a standard forklift truck

as your requirement

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Boss Metal And Plastic Co Limited

Boss Metal And Plastic Co Limited