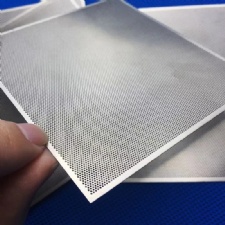

Boss Metal has been widely used in the manufacturing of car speaker grills; many branding car manufacturers or loudspeaker manufacturers benefit from this technology.

Speaker Grill Feature

2, Design flexibility -- Photo etching allows much flexibility on product design, whether it is outer product shape or the hole patterns; there is even no cost for complex designs.

3, Stress and burr-free, smooth surface -- the material temper will not be affected during this process, and it can guarantee a very smooth surface

4, Easy to coordinate with other manufacturing processes such as PVD plating, stamping, brushing, polishing and so on

5, Various material options -- Speaker Grill available stainless steel, copper, brass, aluminum, titanium, metal alloy at the thickness from 0.02mm to 2mm are all available.

Your competitors are using photo etching to supply better products now...Why not have a try?

The perforated metal speaker grille advantages

1, Short lead time, we can finish your sample and goods within your tight deadline.

2, Provide you with etching metal parts with high precision, tight tolerance, for example, 0.1mm material, the tolerance can be 0.02mm.

3, Good price and service; quotation will be provided in 24 hours after getting your inquiry.

4, Low tooling cost.

5, Speaker Grills Can make thinner metals(T=0.04-1.0 mm).

6, High accuracy.

7, Various apertures, shapes and bar combinations.

8, Burr & Stress-free manufacturing method.

9, Short lead time and high volume capability.

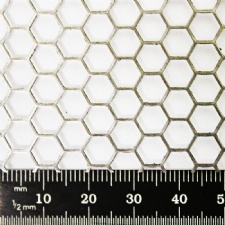

Specification

|

Stainless Steel/Aluminum/metal Etched Speaker Grill for Car Parts |

|

|

Material: |

Stainless steel, aluminum, brass, copper, bronze, iron, precious metals or customize |

|

Size: |

According to customers |

|

Thickness: |

0.03-2mm is available |

|

Technique: |

High precision etching |

|

Hole: |

0.01mm(customize) |

|

Spacing |

0.018mm(customize) |

|

Hole shape: |

Hexagon, oval, round, rectangle, square, or customized |

|

Surface finish: |

Clean .no burr |

|

Features: |

No burrs, No broken point, no plugging holes |

|

Application: |

Automobile Parts, Car speaker, Audio speaker grill or customize |

|

Certificate: |

RoHS,ISO |

|

Inspection: |

Two-dimension inspection machine, magnifier |

Applications speaker grill

- 1, etching processing various kinds of metal, alloy and stainless steel plate, strip,

- 2, thickness and 2mm scope: 0.5 mm, especially for thin sheet below,

- 3: (1), petroleum, chemical, food, pharmaceutical precision filter, filter plate, filter canister, filters (2) electronic industry with a metal plate, plate leakage, lead, lead frame, the metal substrate

- (3)speaker grill for precision optical and mechanical parts, components, plane spring

- (4) friction slices and other parts of the concave and convex surface

- (5) metal plate and the design of complex metal accessories and elegant handicraft

Stainless Steel

We can provide speaker grill meshes with different structures, shapes, holes and surface treatments. Common surface treatments are electroplate, spray paint, laser, anodized, sandblast and polish.

Boss Metal And Plastic Co Limited

Boss Metal And Plastic Co Limited