Wire mesh pallet cages are a type of storage and transport container that are designed to be used with standard pallet racking systems. They are typically made from welded wire mesh panels that are attached to a pallet base, and are used for storing and transporting a wide range of goods.

Overall, wire mesh pallet cages are a versatile and practical solution for storage and transportation, offering a range of features that make them useful for a variety of industries and applications.

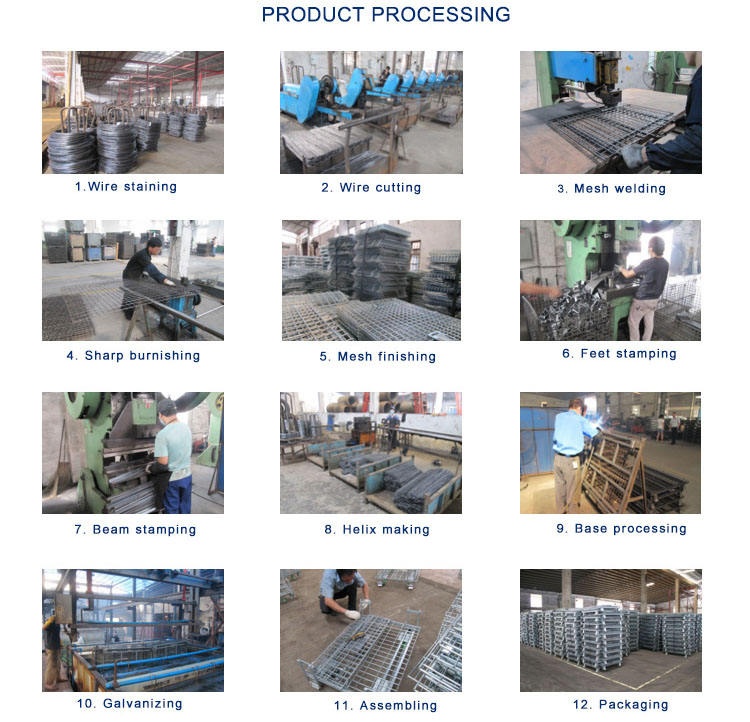

The production flow of wire mesh pallet cages typically involves the following steps:

-

Raw material preparation: The first step in the production of wire mesh pallet cages is to prepare the raw materials. This typically involves sourcing high-quality steel wire, usually in the form of coils, and cutting it to the required length.

-

Welding: The next step is to weld the wire mesh panels together to form the sides, base, and top of the cage. The wire mesh is typically welded using automated welding machines that ensure precise and consistent welds.

-

Frame fabrication: Once the wire mesh panels have been welded together, a frame is fabricated to support the structure. The frame is usually made from steel tubing and is welded to the wire mesh panels.

-

Surface treatment: After the wire mesh containers has been welded and framed, it is treated to prevent rust and corrosion. This is typically done by applying a coat of paint or galvanizing the structure.

-

Final assembly: The final step in the production of wire mesh pallet cages is to assemble the various components. This typically involves fitting the base, sides, and top together and securing them with nuts and bolts.

-

Quality control: Finally, the completed wire mesh containers are inspected to ensure that they meet the required quality standards. This typically involves checking the welds, the finish, and the overall construction of the cage. Any defects are identified and corrected before the cages are shipped to customers.

Overall, the production flow of wire mesh pallet cages involves several complex steps that require specialized machinery and skilled workers. However, by following these steps carefully, manufacturers can produce high-quality wire mesh pallet cages that are durable and reliable.

Here is a table summarizing the specifications of the wire mesh pallet cages mentioned:

| Type | Exter Dim (mm) | Wire Gauge (mm) | Mesh Size (mm) | Loading (kg) |

|---|---|---|---|---|

| ED-1 | 1140x830x980 | 5-12 | 55x113 | 600 |

| ED-5 | 1200x920x1018 | 5-12 | 51x118 | 600 |

| ED-16 | 1200x920x1018 | 4.8-5.8 | 54x115 | 900 |

| ED-21 | 1168x850x988 | 5.8 | 50x110 | 400 |

| ED-22 | 1200x1007x1174 | 5-12 | 62x125 | 600 |

| ED-28 | 1200x1010x1200 | 5-12 | 62x125 | 800 |

Wire mesh pallet cages offer several advantages for storage and transportation, including:

- Space-saving: Wire mesh pallet cages can be folded flat when not in use, which saves storage space compared to traditional storage containers that are bulky and take up more space.

- Durability: Wire mesh containers are made of sturdy materials, such as steel wire and galvanized steel sheets, which makes them durable and long-lasting. They can withstand wear and tear and can be used repeatedly for many years.

- Better visibility: The open mesh design of wire mesh containers allows for clear visibility of the contents inside, which makes it easier to locate items during inventory checks. The open design also allows for ventilation and air circulation, which can help prevent moisture buildup and keep the stored items dry.

- Easy handling: Wire mesh cages have four-way entry points, which makes them easy to handle and move using standard forklifts and pallet jacks. This allows for efficient loading and unloading of items and reduces the need for manual handling.

- Cost-effective: Wire mesh containers are a cost-effective alternative to disposable packaging such as cardboard boxes or plastic bags. They can be reused many times and require less frequent replacement, which helps reduce overall costs.

- Customizable: Wire mesh pallet cages can be customized to fit specific requirements, such as size, shape, and loading capacity. This makes them suitable for a wide range of storage and transportation applications.

Overall, wire mesh pallet cages provide many advantages over traditional storage containers, making them a popular choice for industrial and commercial use.

They can be used in various applications, including:

-

Warehousing: Wire mesh pallet cages are commonly used in warehouses for storing and transporting goods. They can be stacked securely and are easy to move using forklifts or pallet jacks, which makes them ideal for efficient storage and retrieval of items.

-

Manufacturing: Wire mesh containers can be used in manufacturing facilities to store raw materials, work in progress, or finished products. Their open mesh design allows for easy visibility of the contents, which can help with inventory management.

-

Distribution: Wire mesh containers are commonly used in distribution centers and logistics operations for transporting goods from one location to another. They can be loaded onto trucks or shipping containers and secured with strapping or wrapping to prevent damage during transit.

-

Retail: Wire mesh containers are used in retail settings to store and display items such as produce, beverages, or other merchandise. Their open mesh design allows for easy visibility of the contents and can help with organization and restocking.

-

Agriculture: Wire mesh pallet cages are used in agricultural settings to store and transport produce, livestock, or equipment. Their open mesh design allows for ventilation and air circulation, which can help prevent moisture buildup and spoilage of produce.

Boss Metal And Plastic Co Limited

Boss Metal And Plastic Co Limited