Heavy-duty storage containers, also known as butterfly cages, storage cages, pallet cages, etc., are made of high-quality steel that is hardened by cold welding to provide high strength and load capacity. They are designed to be rugged and provide convenient transportation. These containers can be reused, reducing storage and packaging costs for enterprises. They are not only suitable for plant production workshops, warehouses, and transportation turnover but can also be used as a display for supermarket sales and warehouses.

A foldable rolling metal storage cage is an essential logistics storage and transportation container that can store items with fixed capacity stacked neatly for easy inventory access, improving the effective utilization of warehouse space. When not in use, these cages can be folded and stacked to save storage space. There are three types of storage cages commonly used:

- Storage cages with wheels

- Storage cages with feet that can be stacked

- Combination of wheels and feet

These storage cages provide a cost-effective and efficient solution for businesses looking to manage their inventory, storage, and transportation needs.

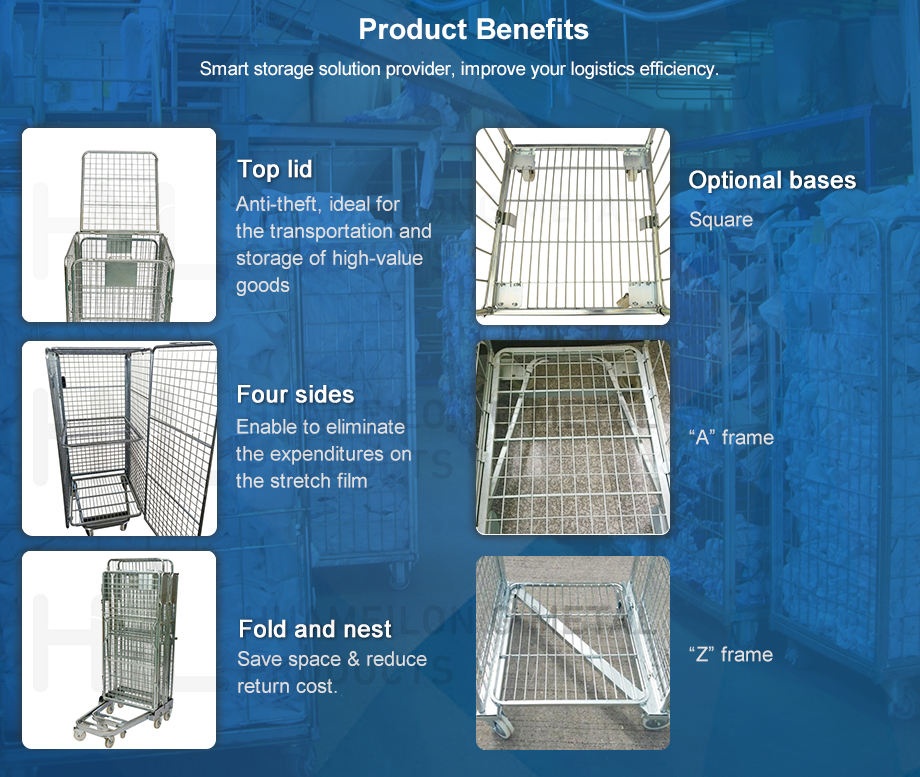

Key Features:

-

Versatile heavy-duty storage containers that combine the functions of pallet and cage for ease of use and convenience.

-

Suitable for a wide range of applications, such as handling, transporting, and storing bulk materials, especially for automotive parts, accessories, and spare parts, hardware, machinery, electronics, and more.

-

Constructed from durable dot welded line steel with U-shaped steel weld support at the bottom for added structural strength.

-

Capable of stacking up to three cages high, making efficient use of storage space.

-

Equipped with a half-drop front gate that allows for easy access to the contents of the cage, even when stacked.

-

Surface treatment with electric galvanization, providing a durable and attractive finish.

-

High load capacity of up to 500-2000kg, providing ample capacity for heavy-duty storage and transportation requirements.

Heavy-duty storage containers have a wide range of applications in various industries. Some of the common applications include:

-

Warehousing: Heavy-duty storage containers are ideal for organizing and storing goods in warehouses. They can be used to store a variety of materials, from small components to large machinery and equipment.

-

Transportation: Heavy-duty storage containers are used to transport goods safely and securely from one location to another. They can be loaded onto trucks, trains, or ships, and can be easily moved using forklifts or pallet jacks.

-

Manufacturing: Heavy-duty storage containers are used in manufacturing plants to store raw materials, work-in-progress, and finished products. They can be easily moved around the plant using pallet jacks or forklifts.

-

Retail: Heavy-duty storage containers can be used as a display in retail stores to showcase products such as hardware, automotive parts, or electronics. They can be stacked or arranged to create attractive displays and are durable enough to withstand heavy use.

-

Construction: Heavy-duty storage containers are used on construction sites to store and transport tools, equipment, and materials. They can be easily moved around the site using cranes, forklifts, or other lifting equipment.

Overall, heavy-duty storage containers are versatile and useful in a variety of industries, making them a popular choice for businesses that need to store, transport, and organize goods.

Here is a table outlining different sizes, specifications, and colors available for heavy-duty storage containers:

| Type/Dimensions(mm) | Length(mm) | Width(mm) | Height(mm) | Load Capacity(kg) per unit | Stacking Layers | Surface Treatment |

|---|---|---|---|---|---|---|

| EG1210 | 1200 | 1000 | 900 | 500-3000 | 4-5 | Powder Coating/Galvanized |

| EG1289 | 1200 | 1000 | 890 | 500-3000 | 4-5 | Powder Coating/Galvanized |

| EG1080 | 1000 | 800 | 850 | 500-3000 | 4-5 | Powder Coating/Galvanized |

| EG8060 | 800 | 600 | 650 | 500-3000 | 4-5 | Powder Coating/Galvanized |

Customers can choose from a range of sizes and specifications to suit their needs, with load capacities ranging from 500-3000kg per unit and 4-5 stacking layers available. The surface treatment can be either powder coating or galvanized, and different colors are available upon request.

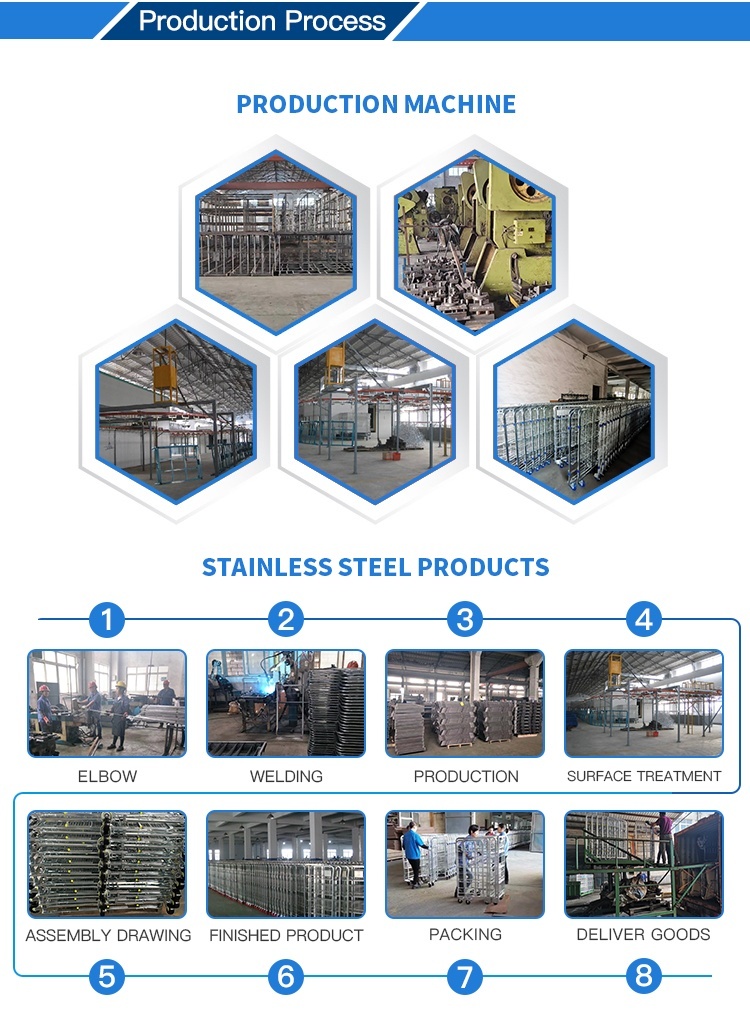

The production process for heavy-duty storage containers generally involves the following steps:

-

Material selection: High-quality steel is selected for the construction of the containers, which is hardened by cold welding to provide high strength and load capacity.

-

Cutting and welding: The steel sheets are cut into the required size and shape using advanced cutting machines. The sheets are then welded together to form the body and sides of the container.

-

Surface treatment: The containers are treated with surface treatments such as powder coating or galvanizing to provide a durable and corrosion-resistant finish.

-

Assembly: The various components of the container, including the body, sides, and base, are assembled together using bolts or welding to form a complete unit.

-

Quality control: The containers undergo rigorous quality control checks to ensure they meet the required standards for load capacity, strength, and durability.

-

Packaging and delivery: Once the containers are completed and quality-checked, they are packaged and shipped to the customers as per their requirements.

Boss Metal And Plastic Co Limited

Boss Metal And Plastic Co Limited