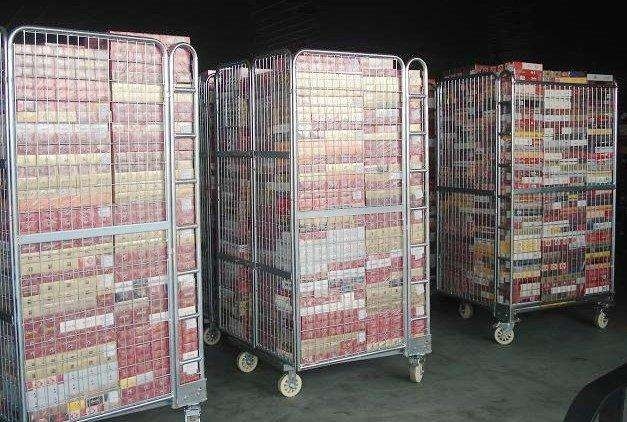

A roll container is a type of storage and transport equipment commonly used in industries such as retail, logistics, and manufacturing. It is a wheeled metal frame with wire mesh sides and often a wire mesh or solid base that can be loaded with goods and rolled around by a person or a machine. Roll containers are designed to be stackable, which allows for efficient use of space during storage and transportation.

Roll containers typically have a variety of components, including doors for easy access to the contents, a baseboard for added support and durability, and castors for smooth movement. The castors can be fixed or swivel, with or without brakes, depending on the intended use of the roll container. The baseboard may be made of a variety of materials, such as wood, plastic, or metal, and may be solid or mesh.

Roll containers come in various sizes and configurations, with different load capacities and mesh patterns. Some roll containers are collapsible, which makes them easy to store when not in use. They can be used to transport a wide range of goods, including boxes, cartons, and loose items.

Roll containers are a versatile and cost-effective solution for storage and transportation needs in various industries. They provide easy access to the contents, improve the efficiency of handling and storage operations, and reduce the risk of damage to goods during transportation.

Roll containers are versatile and useful storage and transportation tools that can be used in a wide range of applications. Here are some of the most common applications of roll containers:

-

Retail and supermarkets: Roll containers are commonly used in retail stores and supermarkets to transport and store merchandise. They are especially useful for moving bulk items such as boxes, bags, and other items in a quick and efficient manner.

-

Warehouses and distribution centers: Roll containers are used in warehouses and distribution centers to transport goods and products from one location to another. They can also be used for temporary storage of items waiting to be shipped or processed.

-

Manufacturing facilities: containers are useful in manufacturing facilities for the storage and transportation of raw materials, work-in-progress products, and finished goods.

-

Hospitals and healthcare facilities: Roll containers can be used in hospitals and healthcare facilities to transport and store medical supplies, linen, and other items. They are especially useful for moving items between different departments or wards.

-

Hotel and hospitality industry: Roll containers are commonly used in the hotel and hospitality industry for the transportation and storage of linens, towels, and other items.

-

Event management: Roll containers can be used at events and exhibitions to transport and store equipment, supplies, and merchandise.

|

|

|

specification roll container:

| Model | Size LxDxH (mm) | With Door Loading (kg) | No Door Loading (kg) | 1x20"GP sets | 1x40"GP sets | 1x20"GP sets | 1x40"GP sets |

|---|---|---|---|---|---|---|---|

| T1 | 800x600x1450 | 105 | 225 | 91 | 195 | 500 | 500 |

| T2 | 850x650x1700 | 90 | 211 | 78 | 182 | 500 | 500 |

| T3 | 950x800x1700 | 75 | 180 | 65 | 156 | 500 | 500 |

| T4 | 1100x800x1700 | 75 | 150 | 65 | 130 | 500 | 500 |

Colour roll container wheel

When selecting colors for roll containers, it's important to consider the environment they will be used in and the company branding. Some companies prefer to use their corporate colors for all their equipment to maintain consistency in their branding. Other companies may choose a bright color to make the roll containers easily identifiable.

As for casters, there are different types and sizes available, including fixed, swivel, and braked casters. The selection of casters depends on the load capacity of the roll container, the type of flooring it will be used on, and the maneuverability required. Consultation with a roll container manufacturer can help in selecting the most suitable caster for the application.

|

|

Color Optional of Roll Container

Roll containers are available in various colors to match different applications and preferences. The most common colors for roll containers are blue, gray, and red, but they can also be customized to match specific branding requirements or preferences.

When choosing a color for your roll container, consider the following factors:

- The environment where the roll container will be used

- The visibility of the container in the workplace

- The branding or color scheme of your company or organization

|

|

|

|

|

|

|

|

|

|

|

|

|

|

How roll containers work ?

Roll containers are designed to transport goods and materials within a warehouse, distribution center, or retail store. They are typically made of metal and consist of a base frame, mesh walls, and a door that can be opened and closed. The roll container sits on four casters that allow it to be easily moved around the facility.

To use a roll container, workers load goods or materials onto the base frame and secure them in place. They then close the door to keep the contents contained and move the roll container to the desired location using the casters. Roll containers can be used to transport a wide variety of items, including boxes, bags, and loose items like apparel or textiles.

Roll containers are often used in conjunction with other warehouse equipment like forklifts or pallet jacks. Workers can load the roll containers onto a pallet or use a forklift to lift and move them. The versatility and portability of roll containers make them a popular choice for businesses looking to improve their logistics and supply chain operations.

|

|

|

|

|

|

|

|

Packing roll containers

The packaging of roll containers usually involves disassembling the components and packing them in a compact manner to minimize the volume and reduce shipping costs. The base frame, doors, baseboard, castors, and bracing are all disassembled and packaged separately. The components are then carefully packed in cardboard boxes, shrink-wrapped, and secured onto pallets for shipping.

During the packaging process, it is important to ensure that all parts are properly labeled and that the packaging is strong enough to withstand any damage during transportation. Additionally, instructions for assembly should be included in the packaging to make it easy for customers to put together the roll container upon delivery.

Efficient and secure packaging is essential for ensuring that the roll containers arrive at their destination in perfect condition, ready to be assembled and put to use.

|

|

|

Boss Metal And Plastic Co Limited

Boss Metal And Plastic Co Limited