Collapsible wire mesh containers are storage containers made of wire mesh that can be collapsed or folded flat when not in use. They are commonly used in industries such as manufacturing, logistics, agriculture, and warehousing for the storage and transportation of goods.

The wire mesh construction of these containers allows for good ventilation and visibility, making it easy to see the contents inside. They are also lightweight and durable, which makes them ideal for frequent use in a busy work environment.

Collapsible wire mesh containers are available in different sizes and designs, and they can be customized to meet specific storage needs. Some of the common types of collapsible wire mesh containers include:

- Foldable wire mesh containers: These are collapsible wire mesh containers that can be folded flat when not in use, making them easy to store and transport.

- Stackable wire mesh containers: These containers are designed to be stacked on top of each other, which maximizes storage space and makes them ideal for use in warehouses.

- Wire mesh baskets: These containers are smaller and are often used for the storage and transportation of smaller items such as tools, parts, and supplies.

Collapsible wire mesh containers are a cost-effective storage solution that can help businesses save space, reduce shipping costs, and increase efficiency in their operations.

dimensions and specifications of the collapsible wire mesh containers mentioned:

| Container Dimensions (LxWxH) | Wire Gauge (mm) | Grid Size (mm) | Leg Height (mm) | Volume (m³) | Stack Level | Capacity (kg) |

|---|---|---|---|---|---|---|

| 1000x800x840 | 4.8 | 50x50 | 100 | 0.52 | 4 | 500 |

| 800x600x640 | 6 | 50x100 | 100 | 0.22 | 4 | 600 |

| 800x600x640 | 6 | 50x50 | 100 | 0.22 | 4 | 800 |

| 1000x800x840 | 6 | 50x100 | 100 | 0.52 | 4 | 1000 |

| 1200x1000x890 | 6 | 50x100 | 100 | 0.84 | 4 | 1000 |

| 1000x800x840 | 6 | 50x50 | 100 | 0.52 | 4 | 1500 |

| 1200x1000x890 | 6 | 50x50 | 100 | 0.84 | 4 | 2000 |

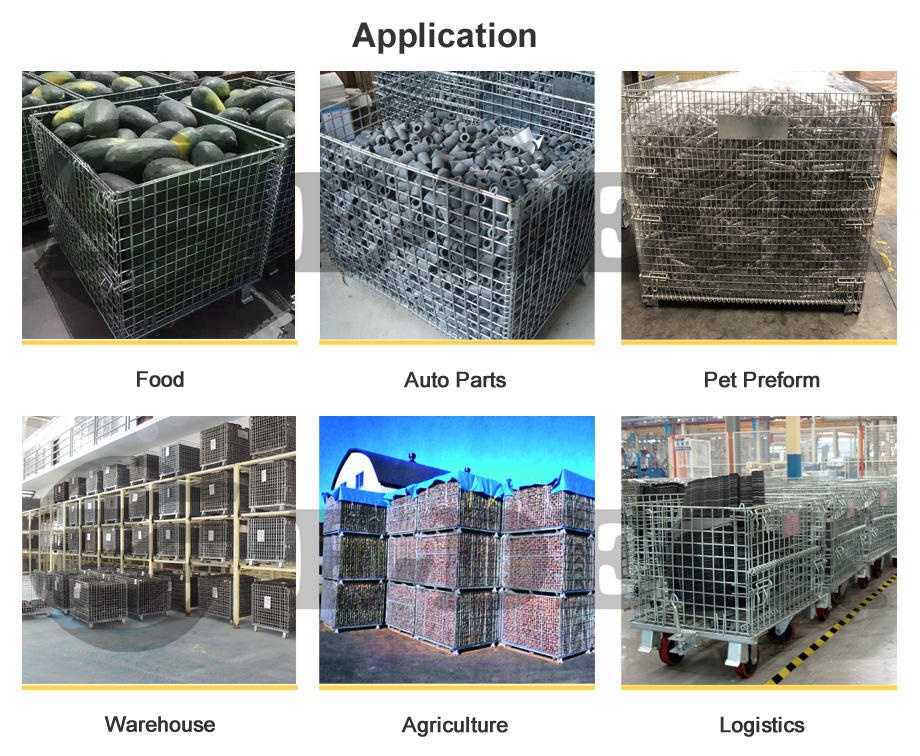

Collapsible wire mesh containers have a wide range of uses and are a versatile storage solution for various industries. Here are some common usages of collapsible wire mesh containers:

-

Warehousing and distribution: Collapsible wire mesh containers are commonly used in warehouses and distribution centers for storing and transporting goods. They can be stacked up to 4 layers high, maximizing storage space, and can be easily moved around with forklifts, elevated cranes, and pallet trucks.

-

Retail and supermarkets: Wire mesh containers are also used in retail and supermarkets for displaying and storing different sizes of goods. The containers can be customized to fit specific shelving units and are easy to move around to different areas of the store.

-

Agriculture and farming: Mesh containers are ideal for storing and transporting fruits, vegetables, and other agricultural products. They allow air to circulate around the produce, keeping them fresh for longer periods.

-

Manufacturing and industrial settings: Wire mesh containers are commonly used in factories and manufacturing facilities to store small or irregularly shaped items. They can be customized to fit specific storage needs and are durable enough to withstand heavy use.

-

Recycling and waste management: Wire mesh containers are also used for recycling and waste management purposes. They can be easily transported to recycling or waste disposal facilities, and the wire mesh construction allows for good ventilation, preventing the buildup of odor or moisture.

Overall, collapsible wire mesh containers are a versatile and cost-effective storage solution that can adapt to various storage needs in different environments.

advantages:

- Space-saving design: Collapsible wire mesh containers can be collapsed and nested inside one another when not in use, taking up significantly less space than traditional wire mesh containers. This feature makes them ideal for businesses with limited storage space.

- Easy to handle and transport: Collapsible wire mesh containers are lightweight and can be easily lifted and moved by workers. When fully assembled, they can be stacked up to four high, making them easy to transport using forklifts or pallet jacks.

- Customizable: wire mesh containers can be customized to meet specific storage needs, with options for different sizes, wire gauges, and grid sizes. They can also be fitted with accessories such as lids and dividers to enhance their functionality.

- Durable: wire mesh containers are made from sturdy metal wire, making them highly durable and resistant to wear and tear. They can withstand heavy loads and rough handling, making them a reliable storage solution for industrial settings.

- Recyclable: wire mesh containers are made from materials that are easily recyclable, contributing to sustainable business practices.

- Cost-effective: Collapsible wire mesh containers are a cost-effective storage solution, as they can be used repeatedly over time. Their collapsible design also saves money on storage space and transportation costs.

The production process for typically involves the following steps:

-

Wire Drawing: The first step in the production process is wire drawing. Raw metal wire is fed through a series of dies to reduce its diameter to the required size.

-

Welding: The wire is then cut to length and welded together to form the mesh panels that make up the container walls and base. Automated welding machines are commonly used for this step.

-

Frame and leg assembly: The mesh panels are then fitted onto a frame made from metal tubing and welded into place. Legs are also added to the frame, which may be adjustable in height.

-

Surface Treatment: The frame and mesh panels are then subjected to a surface treatment, such as galvanizing, to protect them against corrosion and rust.

-

Assembly: Once the mesh panels and frame have been treated, they are assembled together using hinges or clips. Collapsible wire mesh containers are designed to fold down when not in use, so the hinges or clips allow them to be easily collapsed and nested inside one another.

-

Quality Control: Finally, the assembled containers are subjected to quality control checks to ensure that they meet the required standards for size, strength, and durability.

Overall, the production process for collapsible wire mesh containers involves a combination of wire drawing, welding, frame and leg assembly, surface treatment, assembly, and quality control. The process may vary depending on the manufacturer, but these are the general steps involved in producing high-quality wire mesh containers.

Boss Metal And Plastic Co Limited

Boss Metal And Plastic Co Limited